Various types of grain cleaning equipment use different working principles to separate grain particles from impurities. Commonly used separation methods include separation by particle size, separation by specific gravity, separation by natural characteristics of impurities, separation by shape, etc. The cleaning equipment of RICHI machinery is SCY Drum Type Pre-cleaner, SCQZ Powder Cleaning Screen, SFJH Rota-shake Sifter and TCTX Permanent Magnet Sleeve.

Primary Crushing is the pre-treatment process of ultrafine pulverization in aquatic feed processing. Its main purpose is to reduce the particle size difference and variation range of materials, improve the working condition of the ultrafine pulverizer, and increase the efficiency of the ultrafine pulverizer. And guarantee the stability of product quality.

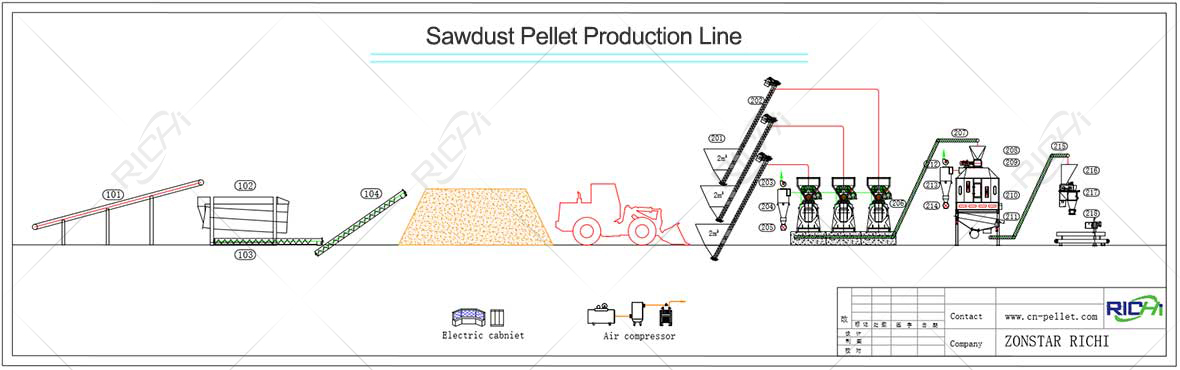

The raw materials will be pulverized, granulated, mixed, and packed from feeding to granulating. A complete feed pellet production line generally has a pulverizing bin, a granulating bin, a mixing bin and a packing bin.This is what we call the Batching Section.

Primary mixing, a single-shaft horizontal ribbon mixer can be selected. At the same time, a grease addition system must be considered on the mixer. The first batching and mixing is also a pre-treatment process of ultrafine crushing, which is mainly to reduce the variation range of the particle size of the material, improve the working condition of the grinder and improve the working efficiency of the grinder to ensure product quality.

To have a homogenous mix, micro materials, premix, minerals and vitamins are added to the mixing machine . Additives are added in certain amounts on each charge. They are crucial on pellet feed’s grade.

Secondary crushing and secondary mixing. In the secondary pulverization process, ultra-fine pulverizer is used, which is equipped with a powerful air separation device, and then enters a rotary classification screen for screening.Various ingredients enter the secondary mixer after secondary dosing.At the same time, the mixer is provided with a liquid adding mechanism for adding grease.In the secondary mixing process, in order to ensure the key to product quality, the mixer must choose a model with good performance.Such as the twin-shaft horizontal paddle mixer, which has high mixing uniformity, high output and fast mixing speed.

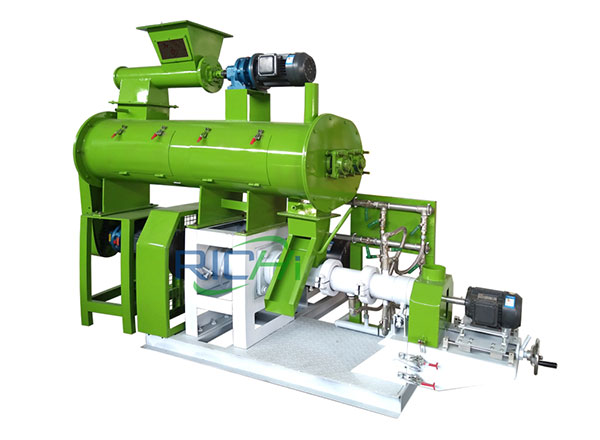

In the extrusion puffing process, the material actually undergoes a cooking process under high temperature, high humidity, and high pressure conditions. Puffed feed, because this kind of feed not only has the advantages of general hard pellet feed --- good palatability, avoids automatic classification of products, facilitates transportation, helps digestion, reduces waste during feeding, etc., but also has unique advantages : The starch has a high degree of gelatinization, and the protein is easier to digest, which improves the animal's utilization rate of the feed. It has excellent floating properties, which is convenient for observing the feeding situation of fish, and it can control water pollution to the greatest extent. These are also the main reasons why extruded feed is widely used.

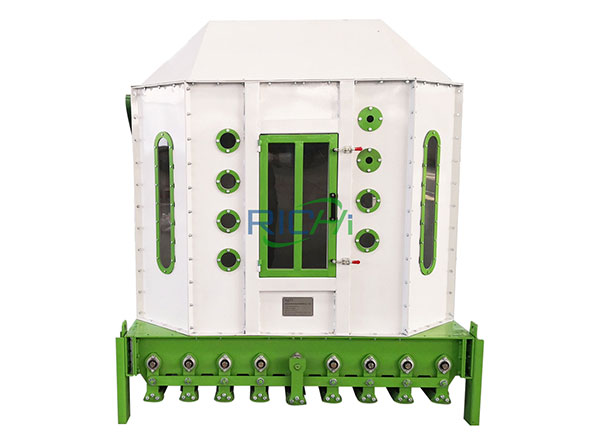

SKLN Series Counterflow Cooler is the most advanced pellet feed cooling technology in the world. It is a new generation of cooling equipment researched and developed. It is mainly used to cool pellet pellets at high temperature after pelleting.

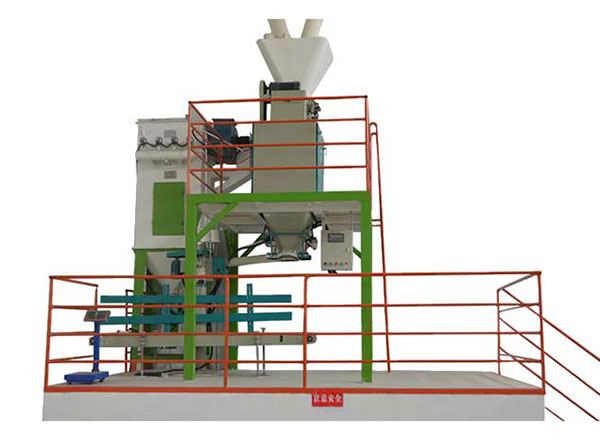

There are three kinds of automatic packaging machines produced by RICHI machinery: powder packaging machines, granule packaging machines and (universal) dual-purpose packaging machines.

Core processing equipment

Contact Us

TCTX Permanent Magnet Sleeve

TBLM Dust Collector

Pulse Dust Remover

SCQZ Conical Drum Powder Precleaner

SCY Drum Pre-cleaner

SLHY Horizontal Ribbon Mixer

Double Shaft Paddle Mixer

Stainless Steel Feed Mixer

Single Roller Double Paddle Mixer

SLHY Horizontal Ribbon Mixer

Double Shaft Paddle Mixer

Stainless Steel Feed Mixer

Single Roller Double Paddle Mixer