Hotline:+86 18574103366

| |

Model:DGP & DSP

Capacity:300KG/H - 4T/H

Applicable: Fish, shrimp and pet food industry

1.With different moulds, the floating fish feed pellet mill for sale can meet different stage fish. The food can be floating 24hours.

2.The floating fish feed pellet machine for sale can produce different shapes feed for fish, dog, cat etc.Through the pretreatment of the feed, it can reduce loss of nutrition and advance the protein ratio. So the feed will be digested easily by animals.3.The floating time can be controlled by the puffing degree adjustment.

3.High temperature and high pressure cooking process can kill the salmonellosis and bacterial infections and also makes the pellets easily to digest.

4.Electric heating device is adopted which can improve the feed expansion rate and pellets floating time.

5.The cutting device can be adjusted to make pellets of different length.

6.The fish pellet mill can make pellet from diameter 1mm-12mm just by changing the mould.

Shrimp feed can be produced either by extrusion, intensive pre-conditioning is a decisive stage of the extrusion process. To prevent expansion of pellets out of extruder the meal ingredients must be kept at a precise temperature. Additionally, because of all the excess moisture added during both preconditioning and extrusion, drying is also mandatory so moisture stability can be maintained in the finished pellets. However, post-conditioning can be eliminated from the extrusion process altogether.

Several benefits of extrusion include precise control over pellet length, a factor that is important in starter feed where pellets should be as small as Ø0,6mm. This process is not possible on a pellet mill without the addition of a crumbler. In addition, control over pellet porosity means they can be easily coated with palatents and oils.

The extrusion technique also allows for substitution of functional starch with nutritional proteins and the expansion control system® allows feed producers to precisely adjust the pellet expansion obtaining full and complete sinkability, the two primary factors for production of high-quality shrimp feed.

The material selection is very wide, such as soybean meal, corn flour, wheat meal, bone meal, meat meal, fish meal and so on. Here is the material requirement:

Shrimp feed pellet extruder maker can also be named as technological process, it forces raw materials into one or more of following process such as mixing, heating, pasting, cutting, extruding, etc. flow through the die, making material eruption gasification. Diameter of the holes which decide the diameter of pellets have various different sizes.

| DGP Dry Type Extruder Mill Parameter | ||||||

| Model | Capacity(t/h) | Main motor power(kw) | Feeder power(kw) | Screw diameter(mm) | Cutter power(kw) | |

| DGP40-Cs | 0.03-0.04 | 3.0*2 | 0.4 | Φ40 | 0.4 | |

| DGP40-C | 0.03-0.04 | 5.5 | 0.4 | Φ40 | 0.4 | |

| DGP50-C | 0.06-0.08 | 11 | 0.4 | Φ50 | 0.4 | |

| DGP60-C | 0.12-0.15 | 15 | 0.4 | φ60 | 0.4 | |

| DGP70-B | 0.18-0.2 | 18.5 | 0.4 | φ70 | 0.4 | |

| DGP80-B | 0.2-0.25 | 22 | 0.4 | φ80 | 0.6 | |

| DGP90-B | 0.30-0.35 | 37 | 0.6 | φ90 | 0.8 | |

| DGP120-B | 0.5-0.6 | 55 | 1.1 | φ120 | 2.2 | |

| DGP135-B | 0.7-0.8 | 75 | 1.1 | φ133 | 2.2 | |

| DGP160-B | 1-1.2 | 90 | 1.5 | φ155 | 3 | |

| DGP200-B | 1.8-2.0 | 132 | 1.5 | φ195 | 3.0-4.0 | |

| DSP Wet Type Extruder Machine Parameter | ||||||

| Model | Capacity(t/h) | Main motor power(kw) | Feeder power(kw) | Screw diameter(mm) | Cutter power(kw) | Conditioner power(kw) |

| DSP60-B | 0.18-0.2 | 15 | 0.4 | Φ60 | 0.4 | 0.75 |

| DSP70-B | 0.25-0.30 | 18.5 | 0.6 | Φ70 | 0.6 | 0.75 |

| DSP80-B | 0.35-0.40 | 22 | 1.1 | Φ80 | 0.8 | 1.1-1.5 |

| DSP90-B | 0.50-0.60 | 37 | 1.1 | Φ90 | 1.1 | 2.2 |

| DSP120-B | 0.70-0.80 | 55 | 1.1 | Φ120 | 1.5 | 2.2-3.0 |

| DSP135-B | 1.0-1.2 | 75 | 1.5 | Φ135 | 2.2 | 3.0-4.0 |

| DSP160-B | 1.8-2.0 | 90 | 2.2 | Φ155 | 2.2-3.0 | 4.0-5.5 |

| DSP200-B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 | 5.5 |

| DSP200-B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 | 5.5 |

Solution

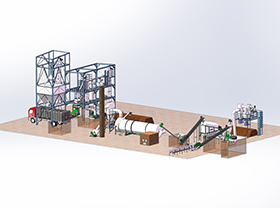

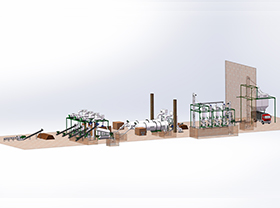

2-2.5 T/H Biomass Wood Pellet Production Line

4-5 T/H Biomass Wood Pellet Production Line

8-10 T/H Biomass Wood Pellet Production Line

24-30 T/H Biomass Wood Pellet Production Line

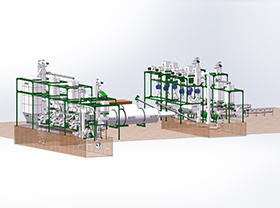

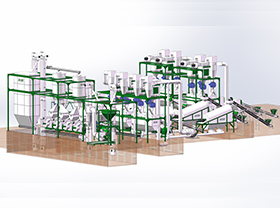

Wood Pellet Plant Production Line

Biomass Pellet Plant Production Line

Alfalfa Pellet Plant Production Line

Organic Fertilizer Pellet Plant Production Line