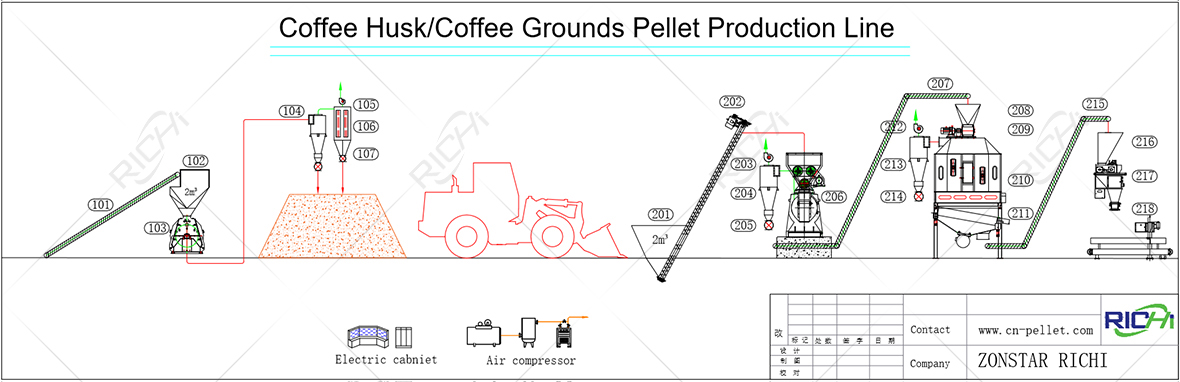

This section is more suitable for the larger raw materials in the early stage, and it is not easy to directly crush or granulate through the crusher. But sometimes this section can be omitted. For example, the sawdust pellet production line can directly pelletize, and this section is not needed.

This section is usually used in biomass pellet production line, forage gress pellet production line and nutshell straw pellet production line. For example, the SFSP hammer mill is used for wood and fruit shells, and the straw/alfalfa/husk/grass crusher is used for grass and straw. Different raw materials are equipped with different types of crusher.

Conveying equipment is mechanical equipment that transports bulk cargo and unit goods from a loading point to an unloading point along a certain route in a continuous manner. The conveying equipment of RICHI machinery includes screw conveyor, scraper conveyor, belt conveyor and Bucket elevator.

To dry materials and remove the moisture from 50% to 15-17%. Itincludes: --Burningstove,tosupplyhotair --Drumdryer --Dischargingcyclone.

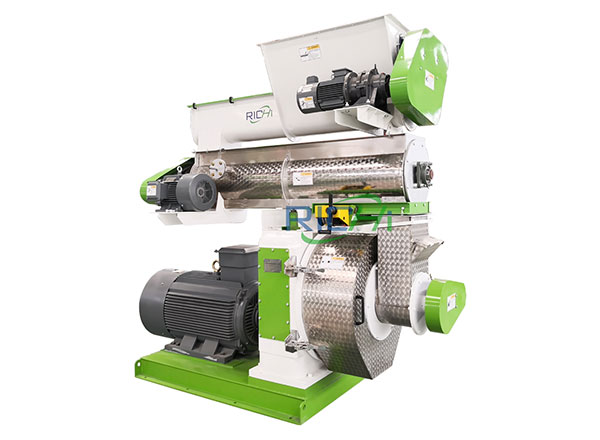

Wood pellet machine, also known as biomass pellet machine, has a wide range of raw materials: straw shells include wood, straw, sawdust, cotton stalks, rice husks, peanut shells, sunflower shells, coconut shells, coffee shells, bamboo, etc. . The grasses are alfalfa, hops, hemp, hay, grass, etc. In addition, there are organic fertilizer granulator, cat litter granulator and so on.

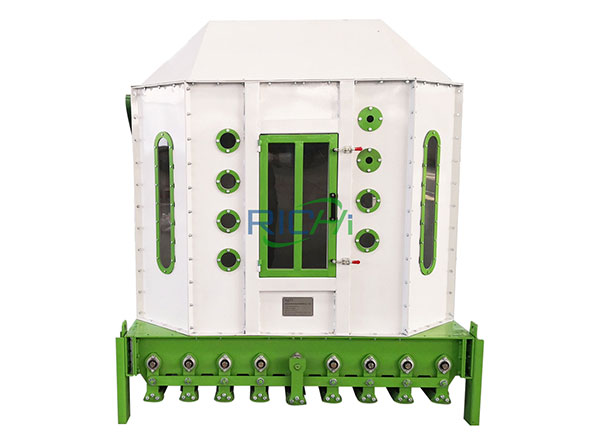

Pellets come out from pellet machine, its temperature is around 70℃, by cooling system, It can cool down to room temperature immediately. By momentary cooling, the hardness of pellets will become more stronger.

The forming rate of pellet machine is around 98 % , so there are still have 2% powder in pellets,by screening, sort out all the powders from pellets.

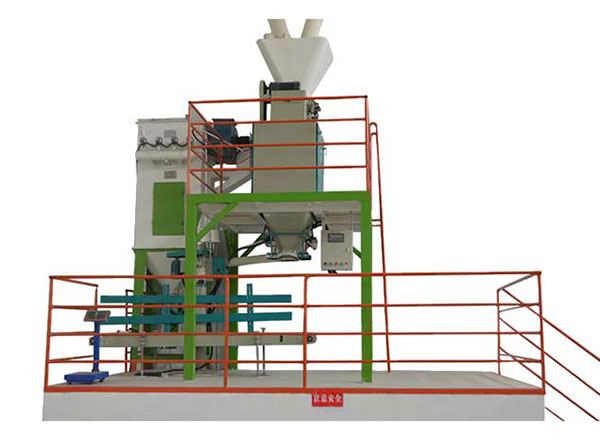

There are three kinds of automatic packaging machines produced by RICHI machinery: powder packaging machines, granule packaging machines and (universal) dual-purpose packaging machines.

A dust collection system is an air quality improvement system used in industrial production to improve breathable air quality and safety by removing particulate matter from the air and environment. Dust collection systems work on the basic formula of capture, convey and collect.