Where are peanuts grown around the world?

Peanuts are grown in the warm climates of Asia, Africa, Australia, and North and South America. As of 2019, the United States planted about two percent of the world acreage of peanuts but grew over five percent of the world’s crop because of higher yields per acre. The bulk of the world’s peanut production comes mainly from, China, India, Nigeria, Sudan, Burma, Argentina and Senegal.

World peanut production totals about 45 million metric tons per year. The United States is the world’s fourth largest producer, after China, India and Nigeria. Worldwide peanut exports are about 3.6 million metric tons, with the U.S. ranking a close fourth behind Argentina, China and India.

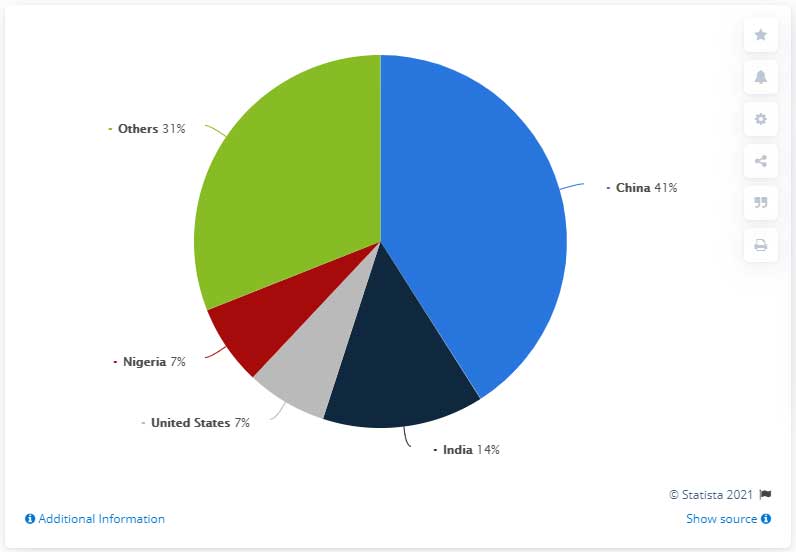

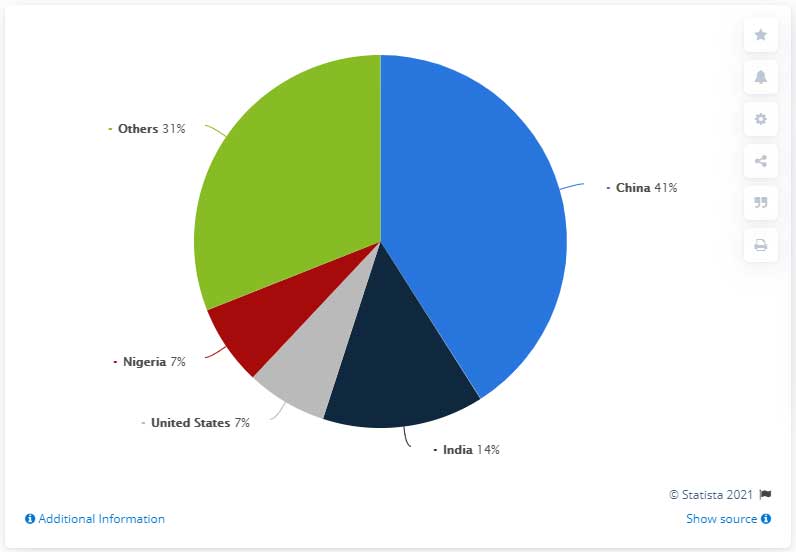

Production share of peanuts worldwide in 2018, by leading country

As of 2018, China was the largest producer of peanuts worldwide, holding an estimated 40 percent share of global production. India ranked second that year, producing about 15 percent of the world's peanuts. While the United States ranked third in terms of peanut production in 2018, the country was by far the top producer of pistachios in 2019/2020. That marketing year, the United States produced roughly half of the world’s pistachio seeds. Iran stood in second place, accounting for a production share of about 30 percent.

How to make peanut shell pellet?

From the characteristic of peanut shell pellet, we can see that peanut shell pellet has so much advantage for our life, but how to get the peanut shell pellet, and what machines should we use?

Heap up raw material. Peanut shell pellet mainly use the peanut shell to be raw material. In order not to affect the production, it had better to prepare enough raw material.

Screening. To improve the peanut shell pellet quality, you should take the the raw material into the screening machine to screen out the impurity.

Drying. Peanut shell pellet production is very strict with the water content of raw material. After screening, transport the the peanut shell into the dryer and use the hot wind to dry it.

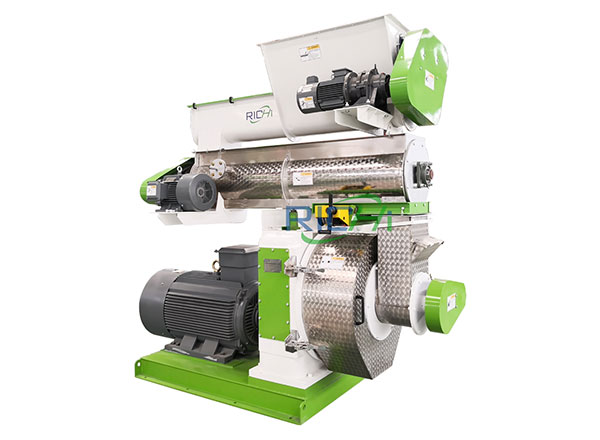

Making pellet. Pellet mill is the key equipment for the production, such a equipment can use various raw material to make pellet fuel, such as peanut shell, saw dust, corn stalk, etc.

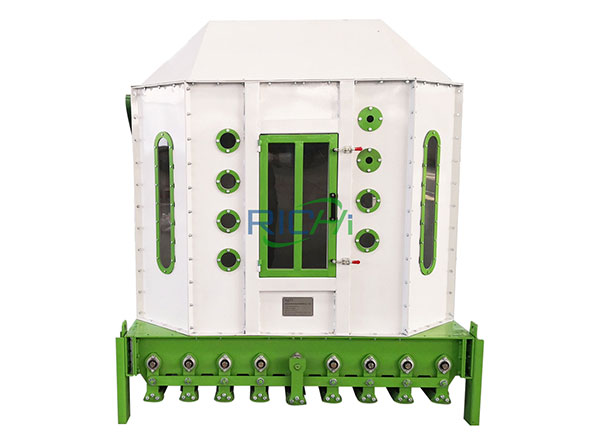

Cooling. The hot peanut shell pellet are easily broken, so after the pellet out from the pellet mill, should take them into the cooling system. Until the peanut shell pellet have the normal temperature can bag them and be put in storage.

Characteristic of peanut shell pellet

1. Shape. The shape of peanut shell pellet is cylindrical. their surface is smooth with a slight sheen. According to different requirement, could produce different size pellet.

2. Heat value. Peanut shell pellet has large densities, so the combustion efficiency is high, when burning, the center temperature can reach more than 1100 degree centigrade, heat value can reach 3700 ~ 4000 kcal / kg, ash content less than 8%. Compare with coal and oil, the peanut shell also has its own unique advantages.

6. Peanut shell or hull are easy to get, which will lower the production cost of peanut shell pellet, providing a big profit margins.

4. Clean and environmental protection. Use the peanut shell pellet fuel can reduce environment pollution. When burning the pellet, ash discharge concentration is less than 40 mg / m3. So use the pellet fuel can improve air quality and avoid greenhouse effect.

7. Peanut pellet fuel is a green biomass energy will lower emission and is environment-friendly.

8. Peanut shell or hull pellets can be used widely either in civil heating and daily energy supplying or in industr

5. Convenient transportation and easy to store. The peanut shell pellet has small volume, so it is easy to store and transport, that can reduce transport cost.

3. High firepower and less ash. Because of high pressure molding and larger density, the peanut shell pellet is heat- resistant with high firepower and less ash. During burning, the pellet can keep shape, no distortion and fall apart. The pellet fuel ash can as the potash fertilizer to return into soil.

Application of peanut shell pellet

- Used for daily life. Because of the high uses ratio, and the feature of easily storage and transport, peanut shell pellet can used for our daily life, like household heating, cooking. It used safety and wholesomely.

- Biomass industrial stove. As the main fuel for the biomass industrial stove, peanut shell pellet mill can replace the coal, petroleum and gas to protect environment, solve the environmental problem. In addition, peanut shell pellet have not corrosion element, that can not corrode the stove. So use the peanut shell pellet can extend the industrial stove’s service life.

Investment Guide

We provide customers with cost-effective solutions that are reliable, professional, affordable and add value to their businesses.