Sugarcane bagasse are the remaining material after squeezing the sugar, very rough, and the protein and energy content is also very low. In many people's minds, bagasse is waste and cannot be reused. But in fact, we can use bagasse processing equipment to make use of it to make feed for cattle, sheep, and even shrimp feed. But feed is not the only use of bagasse. Bagasse can also be processed into bagasse pellets, which can be used as biomass energy for power generation and heating.

There are more than 100 countries produce sugarcane in the world, the largest sugarcane producing country is Brazil, followed by India, China ranked third.Sugarcane, mainly used for producing sugar, is rich in sugar, water, and a variety of vitamins, fats, proteins, organic acids, calcium, iron and other substances that are very beneficial to human metabolism. There are a large number of sugarcane produced in the south of China, so the bagasse here is also in large quantities. In the past, the bagasse is mainly used as boiler fuel to provide energy for sugar production, but the thermal efficiency is very low. Now, we have the biomass pellet fuel and the biomass pellet equipment, so the sugarcane bagasse can be produced as pellet fuel by the sugarcane bagasse pellet mill, that can improve the utilization efficiency of the bagasse.

How to make sugar cane bagasse pellets?

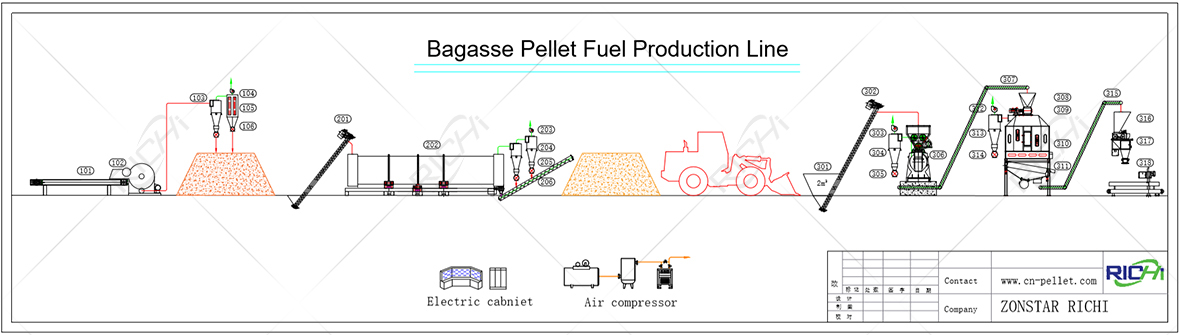

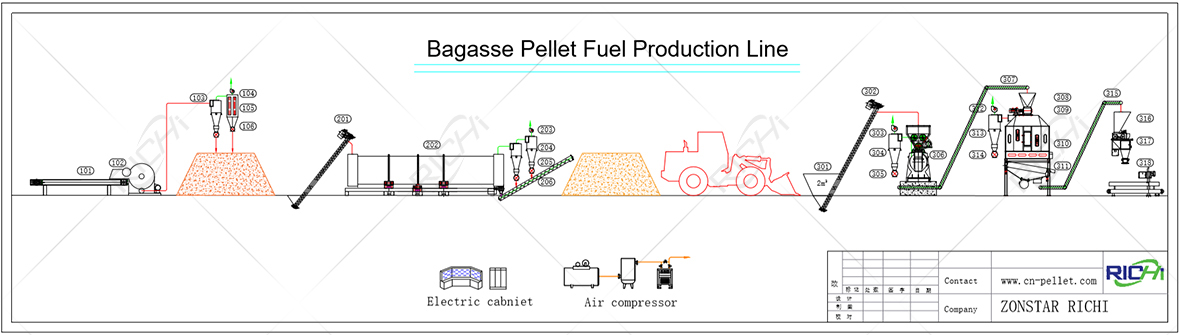

Sugarcane Bagasse Pellet Plant Production Line Flowchart

Sugarcane Bagasse Pellet Plant Production Line Flowchart(1) Sieving. Screen out oversized materials and impurities to ensure that the raw materials meet the granulation requirements. Generally between 2-6mm.

(2) Drying. Granulation of bagasse requires that the moisture content be below 20%. Use a dryer to dry the moisture.

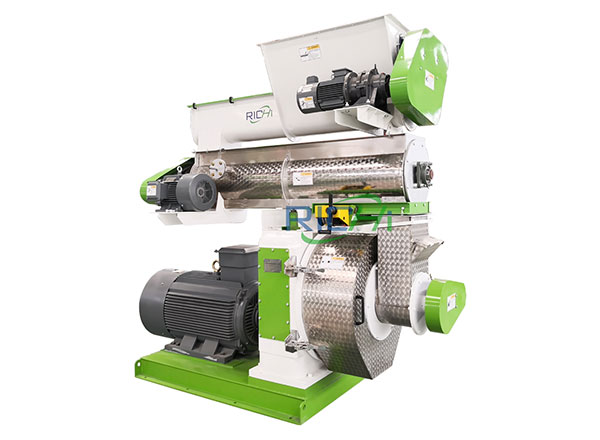

(3) Granulation. The key step is completed by the sugar cane bagasse pellet making machine. The granule quality is good and the output is large.

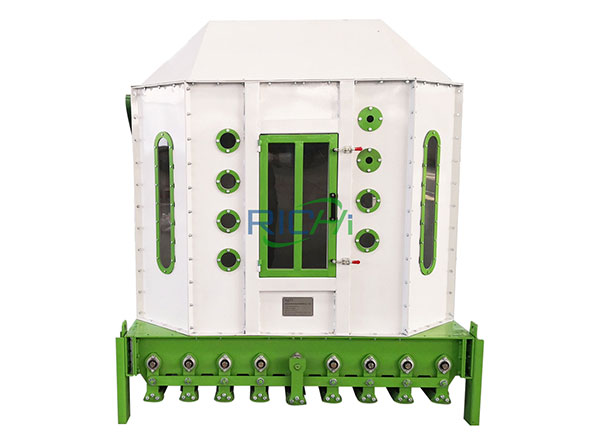

(4) Cooling. Due to the work done by extrusion, the bagasse pellets have a high temperature and need to be cooled before packaging. The counter-current cooler has reasonable design and rapid cooling.

(5) Screening. Through vibrating sieving, qualified bagasse particles are sieved, and other unqualified products are recovered and reused.

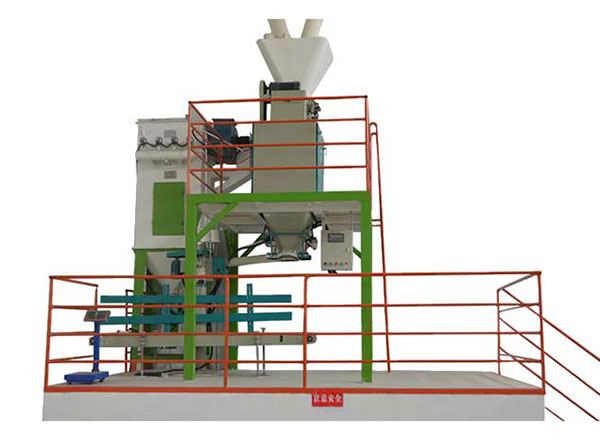

(6) Packaging. Automatic measurement, automatic sealing, save time and effort, improve efficiency and reduce costs.

(7) Dust removal. The dust produced in the production process is recycled for granulation, reducing waste and increasing profit.

Benefits of sugarcane bagasse pellets?

The bagasse pellets are applied in many places because of its convenience and comfort, it has the following advantages:

High return on the investment

Low cost of raw materials, small investment of the equipment, the operation is simple. The ordinary people after simple training can operate the equipment, the human labor cost is very low, coal prices fluctuate. These factors ensure better returns on investments.

Wide application ranges

Bagasse pellets are easy to use and store. It can be employed in heating, living stoves, hot water boilers, industrial boilers, biomass power plant and so on to replace firewood, coal, fuel oil, liquefied petroleum gas. The family unit is also applicable; the burning effect is good, which can meet the cooking, heating, bathing needs, especially the necessities for biomass power plant.

Environmental benefits

Bagasse pellets benefits the environment, bagasse pellets are carbon neutral, which means the emissions of CO2 produced by itself is absorbed by itself during growth. They do not release other air polluting gases into the air.

Renewable

Different from fossil fuels such as coal and natural gas which is expendable (formed in a very long time), bagasse pellets are renewable, because sugarcane grows every year, and we can have endless supply of raw materials.

Independent

The price of coal, oil and gas are controlled by the government, With the more demand for energy and the less fossil fuels, no one can assure the stability of their prices. However, the cost of bagasse pellets can be controlled.

Turn waste into wealth

Under the background of the global shortage of energy, the bagasse pellets is a representative of turning “waste” into wealth, the sugarcanes were made full use of, in addition to this, also increases the income of farmers.

Application

As a Fuel Source

Because bagasse pellets are created from sugar production, they are mainly used as fuel sources for sugar factories. When large quantities of bagasse are burned, an excess of energy in the form of heat is released. This can often power an entire sugar mill. Since such a large amount of energy is created through combustion, excess energy can be sold onto the consumer electrical grid to create electricity.

Some sugar mill owners sell their excess bagasse pellets to other factories with boilers or export them to foreign countries. Recently many East Asian countries such as China have started imported large quantities of bagasse pellets. An average size power plant usually consumes over 10,000 tonnes of bagasse pellets every month.

As Animal Feed

Another way to use bagasse pellets is to feed them to your livestock. To use bagasse as feed it must be processed further by fermenting it. In this step of the process, enzymes and molasses are added to the pellets. Many countries market their pellets as 'fiber rich'.

As Pulp and Paper

In countries such as India, China, Colombia, Iran, Thailand and Argentina, bagasse is used in lieu of wood to create paper and pulp. Bagasse has good qualities for creating paper for mass production and distribution. It is also used to create thicker material boxes and boards as a substitute for plywood. Many companies even use it to build furniture.

Investment Guide

We provide customers with cost-effective solutions that are reliable, professional, affordable and add value to their businesses.