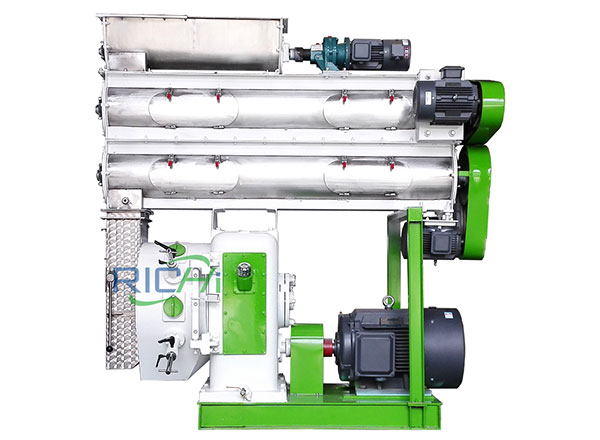

Cat litters pellets are a convenient modern-day solution for pet lovers. Cat litter pellets are growing in demand as owners of the gentle four-pawed animal are increasingly turning to litter pellets. It is estimated that about 87% of cat owners use litter pellets. Unlike pet food manufacturing, cat pellets is a matured industry which follows a standard manufacturing process. A large-scale manufacturing process consists of various parts or production lines such as crusher or hammers mill, feeders, mixers, cat litter pellet mill machine, dryer, and packaging units.

Global Cat Litter Market

Global cat litter market: United States, Canada, Mexico, Brazil, Argentina, other countries in South America, Germany, France, Italy, United Kingdom, Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, other European countries, Japan, China, India, South Korea , Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, rest of Asia Pacific, UAE, Saudi Arabia, Egypt, South Africa, Israel, rest of Middle East and Africa.

How to make Cat litter?

There are many raw materials for the cat litter pellet production line. Here is a brief introduction to the steps of the tofu cat litter production line. If you want to know about other cat litter raw material production lines, please contact us!

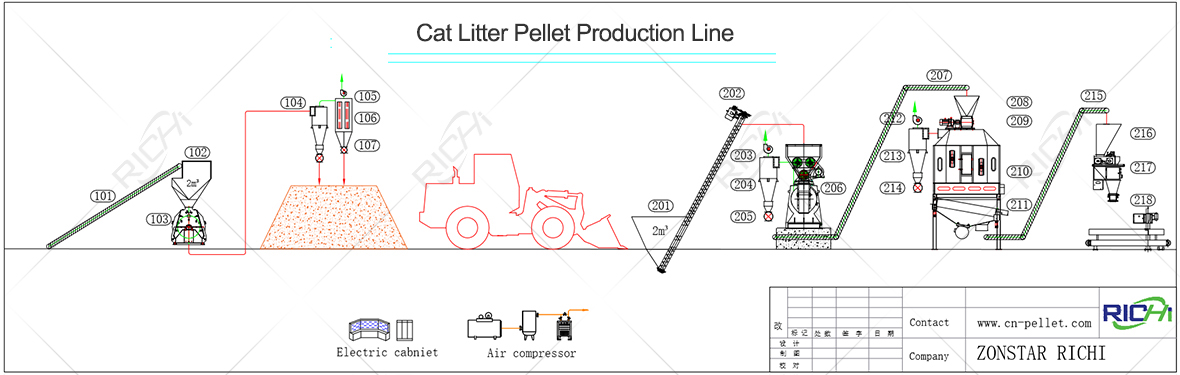

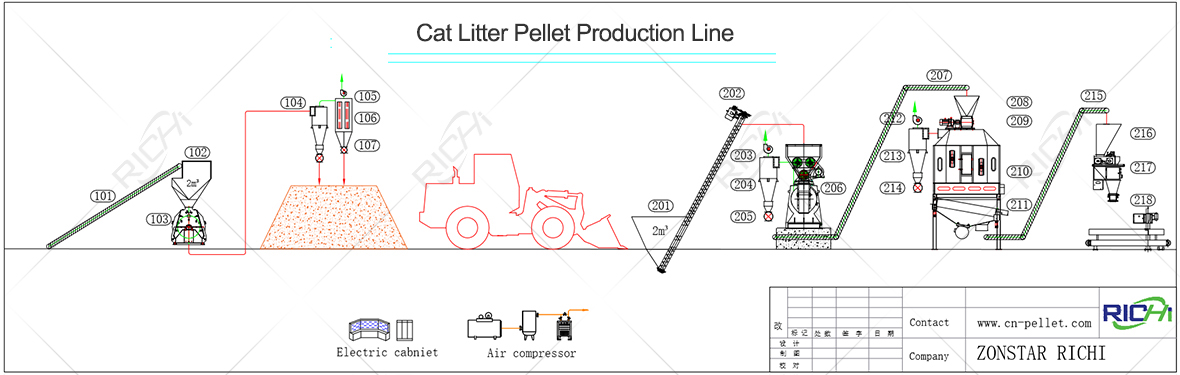

Cat litter Pellet Plant Production Line Flowchart

(1) Material storage

The raw materials of the project are soybean fiber, corn starch, and walnut wood in bags, all of which are purchased. The raw material truck is a closed transportation vehicle, which will be stored directly after entering the factory.

(2) Feeding, batching and mixing

The raw materials are transported to the workshop by the human material trolley, and they are manually put into the feed opening of the elevator in the batching room. The weight of the materials is automatically measured, and the materials are conveyed to the mixer by the enclosed screw elevator. Water is added in proportion, and the materials are fully mixed and the mixing is confidential. Particulate matter is generated in the manual feeding process. An air collecting hood is arranged above the three sides of the feeding place.

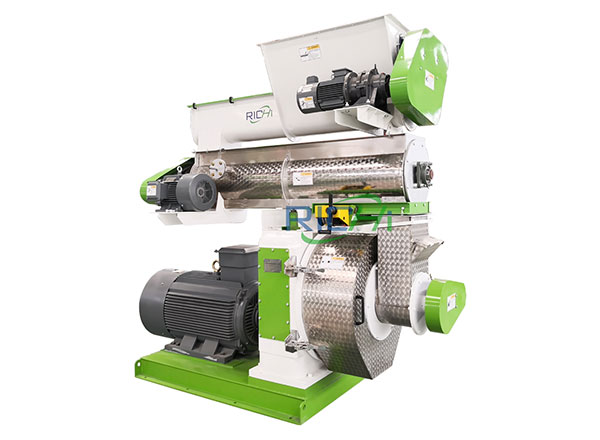

(3) Granulation

The uniformly mixed wet material is transported to the granulator by the closed elevator. The steam enters the granulator through the pipeline and directly contacts the material for granulation. The granulation is confidential and the steam does not overflow. The wet material is squeezed in the granulator. Segment products are cut out by the ring holes.

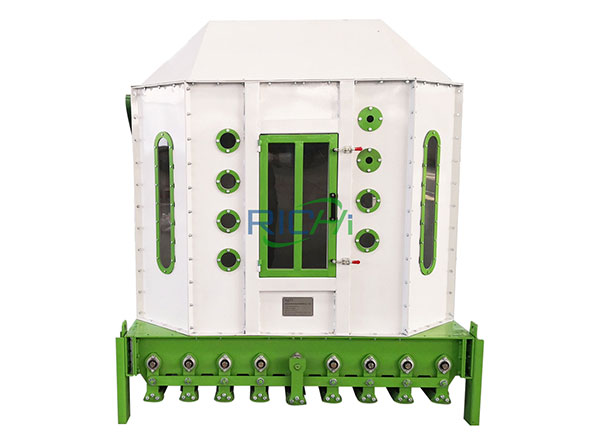

(4) Drying

The finished product of granulation is conveyed to the drying bin by the airtight conveyor belt, and dried by steam heating. The drying bin is airtight. There is an induced draft fan in the drying bin. The fan is connected to a pulse-type bag filter. Hard and strong. After the particulate matter generated during the drying process is processed by the bag filter, it is discharged with an exhaust cylinder shared with the processed particulate matter.

(5) Screening

After the material is dried, it becomes a large particle product. The dried product is transported to a vibrating screen by a conveyor belt for screening. According to product requirements, product particles with a particle size of <5mm are unqualified products and are screened through the screening process. In addition, unqualified products are collected and reused for production. The materials move with the vibration of the vibrating screen into the packaging process. After the particles produced in the screening process are processed by the bag filter, they share an exhaust cylinder with the processed feeding and drying particles.

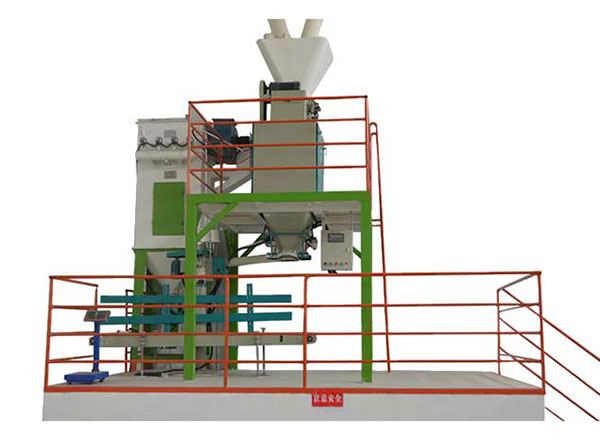

(6) Packaging

The materials are sent into the packaging machine in equal amounts along with the vibration, and the packaging machine automatically bagging and sealing. After the bagging is completed, the products are waiting for sale.

Pros and Cons of five cat litter pellets

1. Tofu cat litter

This type includes corn cat litter, green tea cat litter, etc. The same as pine wood pellet cat litter, tofu cat litter is in granular form.

Pros: It has similar features with wood pellet cat litter, but higher deodorization effect. It is clean and acceptable to most cats. It is easy to clean when the cat bring it out of the litter box.

Cons: The price is higher than other types of cat litter.

2. Wood pellet cat litter

Pros:

A. Good water absorption ability.

B. Less peculiar smell

C. Low wear rate, long use time.

D. Convenient to use, rush it into the toilet after use.

E. According to research, reduce the risk of Feline Lower Urinary Tract Diseases.

Cons:

A. Wood pellet cat litter is easy to be damp.

B. Some cats don’t like the flavor and touch of wood, and even refuse to use.

C. The price of wood pellet cat litter is a little higher than other materials.

D. Cats may take out the sawdust in wood pellets and pollute your room.

3. Bentonite cat litter

Pros: easy to cake when wet. Low price. Most cats can accept it. Deodorization effects is general.

Cons: contain ash and dust, especially when the particle is small. Large weight. Easy to get stuck in the cat pads.

Notes: if you use bentonite cat litter, you’d better choose a fully enclosed single layer litter box to prevent flying dust. Or you can mix bentonite with some silica gel cat litters.

4. Paper pellet cat litter

A. Paper pellet cat litter is made of waste papers like newspapers. Some of them contains active carbon.

B. Paper pellet cat litter is a kind of soft litter. Paper pellets are similar with bentonite cat litter in size and hardness. Some paper pellets cat litter contains active carbon, which can improve the deodorization effects.

C. Paper pellet cat litter are less easy to cake. Although some paper pellets can cake in use, it will become a mass of paste. However, the paper pellets would turn gray after wet by urines, which are easy to recognize and clear away.

5. Silica gel cat litter

Pros: Better deodorization effect than bentonite. Light weight. Long use time.

Cons: large particle size. Some silica gels contains harmful additives, which may be eaten by cats. Notes: Some cats don’t accept pure silica gel litter, you can mix it with bentonite or other types of cat litters. Silica gels can absorb cat urine, so it has high deodorization effect at first. When the color turn yellow, you need to discard it.

How To Choose Suitable Cat Litters?

To choose cat litter, you should pay attention to the following aspects.

1. The fragrance shouldn’t be too strong. Too strong fragrance means it contains many additives, and easy to cause sensitization. Cat litters with fragrance has worse odor-removal effect than those without it. Cats have shaper sense of smell than human, the fragrance to human may be pungent to cats. They don’t feel good with such scent.

2. Too much ash and dust is harmful. Dust in the cat litter does harm both to cats and human. Cats is used to bury their dung. When they dig the cat litter, the dust will fly and pollute the room.

3. Good feeling to the cat-pad. Cats would like to dig with their pad only when they feel good. If they don’t like the touch, they are unwilling to dung on it.

4. The litter ingredients are healthy. Buy cat litter from formal manufacturers who can ensure the quality and health. Too cheap cat litter usually have bad deodorize and water absorption effects.

5. High coagulative and water absorption ability. According to tests, pine wood pellet cat litter has the best absorption ability, then comes Tofu and corn cat littler, the last are bentonite and crystal cat litter.

Investment Guide

We provide customers with cost-effective solutions that are reliable, professional, affordable and add value to their businesses.