Coconut

Commonly referred to as the “tree of life”, the coconut has a wide range of uses. The coir, a natural elastic fiber taken from coconut husks, can be used to make floor mats, brushes, ropes and strings. Coconut leaves can be used to make brooms, baskets, roofing thatches and temporary sheds. Coconut lumber is used for building houses and furniture. Fuel and charcoal can be produced from husks and coconut shells. Coconut oil, coconut milk and copra are among products extracted from coconut meat. Coconut water has gained popularity over the last few years—not only as refreshment but also as a sports drink. In addition to that, coconuts have been used to create musical instruments in China, Vietnam, the Middle East and Eastern Europe. In the Philippines, alcoholic beverages are created from coconuts.

While the coconut is a staple in many households in tropical regions, it is still considered exotic by most Western countries. Agriculturists classify the coconut as a drupe which is a fruit, a nut and a seed in one. Many Asian cultures consider the coconut as a potent cure for illnesses such as nausea, rash, fever and the like. Moreover, nutritionists claim that coconuts contain naturally sterile electrolytes, high amounts of fiber, lauric acid, manganese, potassium and phosphorus.

Recently, as governments gradually enhance their support for biomass fuel industry, more and more people have seen the market prospects and profit margins of coconut shell pellets. In the main plantation and supply countries, start using coconut shell pellet plant production line is an excellent chance.

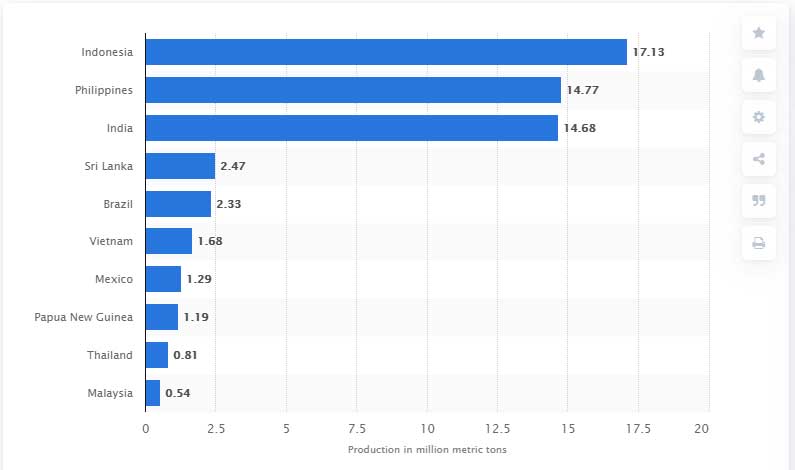

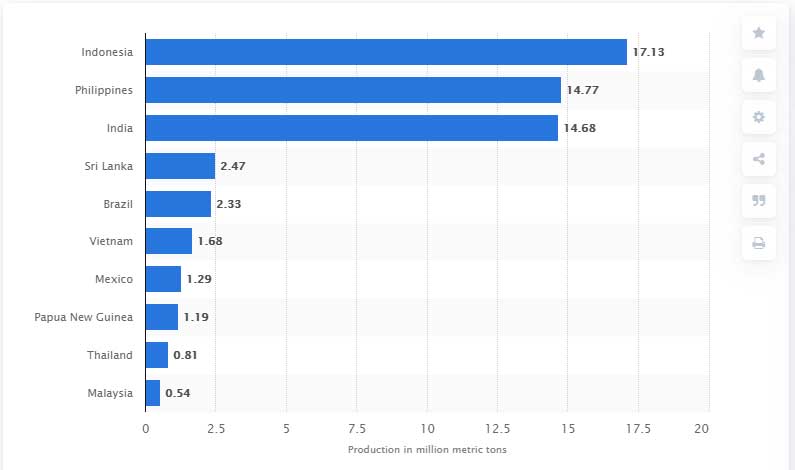

Global leading producers of coconuts 2019

Indonesia is the world's leading coconut producer in 2019, with about 17.13 million metric tons of coconuts produced. That year, India was the third largest coconut producer in the world, accounting for around 14.68 million metric tons of global production volume.

Top 10 Coconut producing countries in the world

Indonesia

Philippines

India

Sri Lanka

Brazil

Viet Nam

Mexico

Papua Gunia

Thailand

Malaysia

How to Make Coconut Shell Pellet?

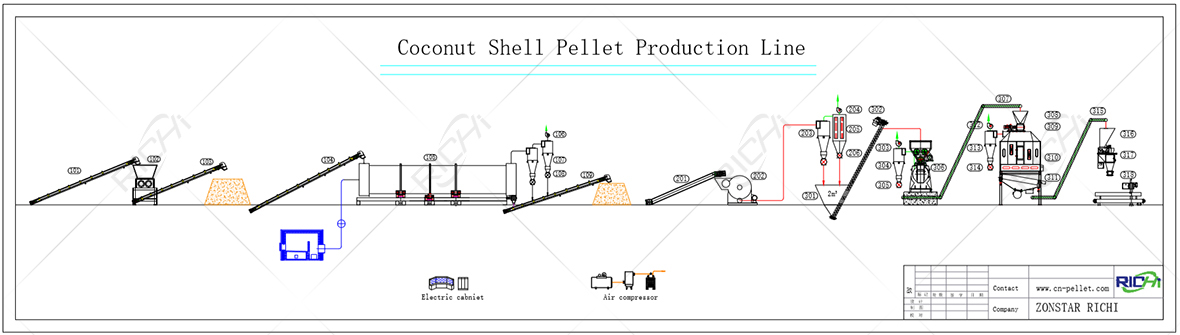

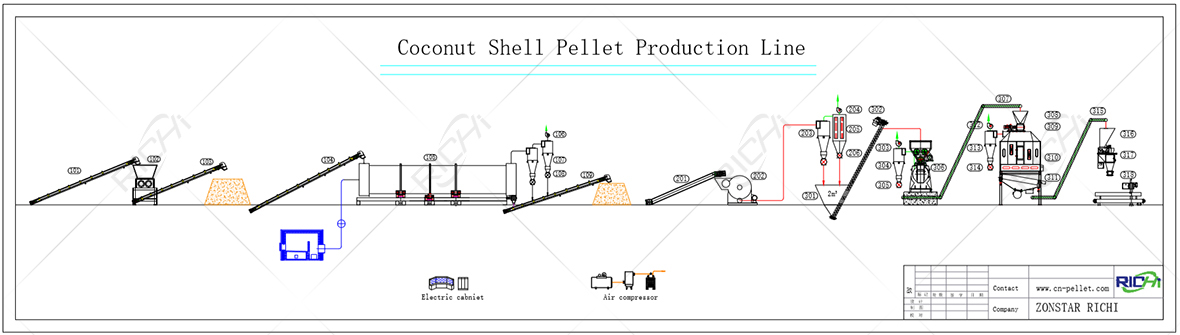

Coconut Shell Pellet Plant Production Line Flowchart

Coconut Shell Pellet Plant Production Line FlowchartCrushing

As the first step of coconut shell pellet line, crushing means to grind large raw materials into smaller particles or powder. When coconut shells are sent into crushing chamber, the hammers which are rotating speedily under the driving force of rotor will beat them hard. After enough impact and friction, they’ll be squeezed out through the screen with a much smaller diameter, less than 5mm.

Drying

Before being sent into wood pellet machine, coconut shells should be dried first. rotary drum dryer is chosen for coconut shell pellet line. Mainly composed of air heater, blower and drying pipe, rotary drum dryer is designed for processing large amounts of raw materials. What should be noticed is that the drying degree of coconut shells should be well controlled. Too dry may be hard to mold, while too wet will reduce the manufacturing efficiency and speed. Generally, 10%-17% of moisture content is recommended.

Pelletizing

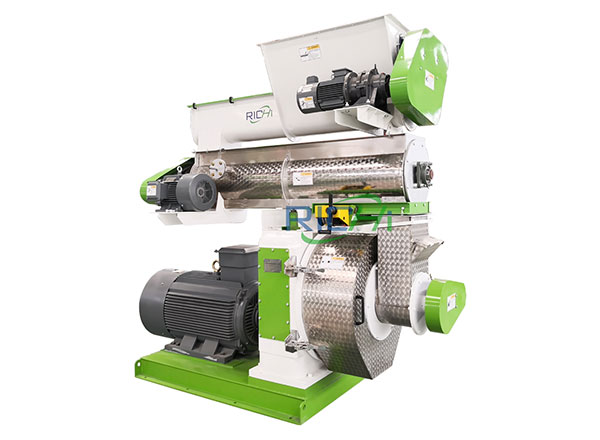

As the core part of the whole procedure, device used to process coconut shell materials into pellets is classified into ring die pellet mill and flat die pellet mill, with larger and smaller capacity respectively.

After being crushed and dried, coconut shells are fed into pelletizing chamber where ring die rotates under the driving force of rollers. Between the space of die and rollers, they are repeatedly pressed and impacted under certain high temperature, which changes their shapes, densities and combustion features. At last, reshaped shells are extruded out through die holes and discharged from ring die pelleting machine.

Cooling

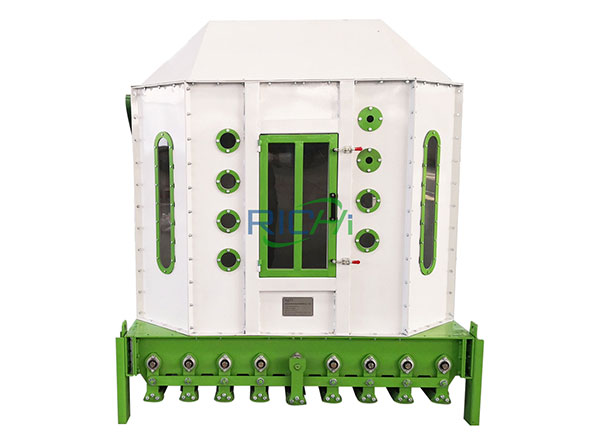

Please be aware that produced coconut shell pellets shall not be packed and stored before cooling process. First, if put these pellets with more than 85℃ in a sealed bag, their quality will be affected. Second, about 15% of moisture content may lead to their mildew or breaking back to powder. Third, too high temperature may cause malfunction of subsequent biomass pellet packing machine.

Among various kinds of cooling machines, counter flow pellet cooler is adopted for coconut shell pellet line. It cannot only cool coconut shell pellets to 3-5℃ but also reduce their moisture content by about 5%, having the characteristics of excellent efficiency, automatic discharging, quality damage prevention, etc.

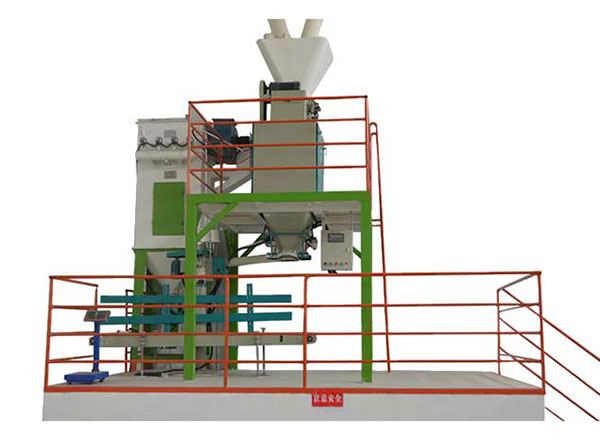

Packaging

Last but not least, coconut shell pellets should be appropriately packed. In the process, you only need to place the bags in proper place. All the following filling, weighing, conveying, sewing and sealing are done automatically. Weighing sensor and adjuster are designed on biomass pellet packing machine. When set weight is reached, bags with coconut shell pellets will be automatically delivered to the sewing part by belt conveyor.

Application of Produced Coconut Shell Pellets

Because of rich raw materials and convenient processing, the products manufactured from coconut shell pellet production line are widely used to replace fossil energy which will release carbon dioxide, sulphur dioxide, nitrogen oxides, etc.

1. Industrial medium and small boiler: applied in biomass fuel plant, power station, wood processing factory, chemical plant, fertilizer factory, etc.

2. Household small stove: they can be used not only for city’s heating supply but also in such service industries as hotel, restaurant and bath.

Investment Guide

We provide customers with cost-effective solutions that are reliable, professional, affordable and add value to their businesses.