Hotline:+86 18574103366

| |

Model:DGP & DSP

Capacity:300KG/H - 4T/H

Applicable: Fish, shrimp and pet food industry

1. Key parts have long service life as they are processed through vacuum quench treatment with high processing precision.

2. Operating parts adopt the humanization design which makes the machine easy to operate.

3. Salmonellosis and bacterial infections can be killed during the high temperature and high pressure pelletizing process, which can also make pellets easy to digest and absorb.

4. Floating pellets made by this wet type fish feed extruder have high quality which can float on the water for more than 12 hours.

5. Raw materials can be fully cooked as the boiler provide hot steam into the conditioner continuously, so the nutritional value of the feed pellets can be improved.

6. Sizes of the feed pellets can be adjusted according to the customer requirement by changing different molds.

Fish feed pellet extruder machine for sinking & floating can be divided into two types: Dry type fish feed extruder and Wet type fish feed extruder.

1. Dry type fish feed extruder does not need the steam boiler while the wet type is with the conditioner and need to equip the steam boiler. So the dry type fish feed pellet extruder machine is cheaper and easier to use and operate

2. The feed pellet made by wet type fish feed pellet machine is more smooth and with better quality because the material is ripen and mixed enough in the conditioner compared with the dry type extruder.

3. The capacity of the wet type is higher than the dry type feed pellet extruding machine, so usually the wet type fish feed extrusiong machine is suitable for large feed pellet factory while the dry type fish feed pellet machine is better and economic for the small and medium size user or factory.

The material selection is very wide, such as soybean meal, corn flour, wheat meal, bone meal, meat meal, fish meal and so on. Here is the material requirement:

The heart of the extruder machine working is: preconditioning, cooking and die shaping. With boiler continuously providing hot steam into the conditioner, mixed materials from fish feed mixer can be fully cooked and the nutritional value is improved. The cooking process can cause a high level of gelatinization of starches, results in feeds with good water stability. The fish feed extruder is a long barrel with a screw auger inside which is specially designed to subject feed mixtures to high heat and steam pressure. When feed exits the die at the end of the barrel, trapped steam blows off rapidly, the soft warm pellets expand, and a low density floating pellet is produced. After that a cutting device will cut the formed pellets into different length as required. The extruder is very versatile, and can make feeds with many different characteristics.

Attentions: our fish feed extruder is of single screw design. The pellets extruded from pellet mill is about 80℃ and moisture content is 18%-20%, so you should equip a dryer and cooler if the capacity is more than 500kg/h. While for small capacity, you can dry them in the sun. We also provide technical formula for making floating fish feed pellets after placing order.

| DGP Dry Type Extruder Mill Parameter | ||||||

| Model | Capacity(t/h) | Main motor power(kw) | Feeder power(kw) | Screw diameter(mm) | Cutter power(kw) | |

| DGP40-Cs | 0.03-0.04 | 3.0*2 | 0.4 | Φ40 | 0.4 | |

| DGP40-C | 0.03-0.04 | 5.5 | 0.4 | Φ40 | 0.4 | |

| DGP50-C | 0.06-0.08 | 11 | 0.4 | Φ50 | 0.4 | |

| DGP60-C | 0.12-0.15 | 15 | 0.4 | φ60 | 0.4 | |

| DGP70-B | 0.18-0.2 | 18.5 | 0.4 | φ70 | 0.4 | |

| DGP80-B | 0.2-0.25 | 22 | 0.4 | φ80 | 0.6 | |

| DGP90-B | 0.30-0.35 | 37 | 0.6 | φ90 | 0.8 | |

| DGP120-B | 0.5-0.6 | 55 | 1.1 | φ120 | 2.2 | |

| DGP135-B | 0.7-0.8 | 75 | 1.1 | φ133 | 2.2 | |

| DGP160-B | 1-1.2 | 90 | 1.5 | φ155 | 3 | |

| DGP200-B | 1.8-2.0 | 132 | 1.5 | φ195 | 3.0-4.0 | |

| DSP Wet Type Extruder Machine Parameter | ||||||

| Model | Capacity(t/h) | Main motor power(kw) | Feeder power(kw) | Screw diameter(mm) | Cutter power(kw) | Conditioner power(kw) |

| DSP60-B | 0.18-0.2 | 15 | 0.4 | Φ60 | 0.4 | 0.75 |

| DSP70-B | 0.25-0.30 | 18.5 | 0.6 | Φ70 | 0.6 | 0.75 |

| DSP80-B | 0.35-0.40 | 22 | 1.1 | Φ80 | 0.8 | 1.1-1.5 |

| DSP90-B | 0.50-0.60 | 37 | 1.1 | Φ90 | 1.1 | 2.2 |

| DSP120-B | 0.70-0.80 | 55 | 1.1 | Φ120 | 1.5 | 2.2-3.0 |

| DSP135-B | 1.0-1.2 | 75 | 1.5 | Φ135 | 2.2 | 3.0-4.0 |

| DSP160-B | 1.8-2.0 | 90 | 2.2 | Φ155 | 2.2-3.0 | 4.0-5.5 |

| DSP200-B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 | 5.5 |

| DSP200-B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 | 5.5 |

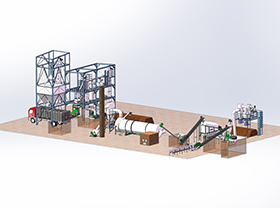

Uzbekistan 5 T/H High Efficiency Sinking Fish Feed Pellet Making Plant Project

Country: Tashkent, Uzbekistan

Capacity: 5 T/H

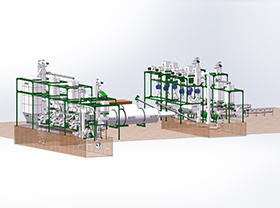

Puerto Rico 1200-1500 KG/H High Quality Fish Feed Pellet Mill Plant Project

Country: Puerto Rico

Capacity: 1200-1500 KG/H

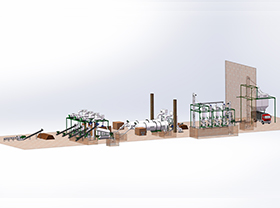

Bolivia Easy to Operate 100-150KG/H Fish Feed Extruder Project

Country: Bolivia

Capacity: 100-150KG/H

Solution

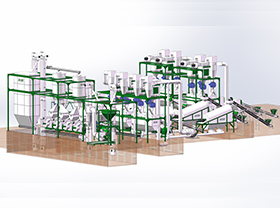

2-2.5 T/H Biomass Wood Pellet Production Line

4-5 T/H Biomass Wood Pellet Production Line

8-10 T/H Biomass Wood Pellet Production Line

24-30 T/H Biomass Wood Pellet Production Line

Wood Pellet Plant Production Line

Biomass Pellet Plant Production Line

Alfalfa Pellet Plant Production Line

Organic Fertilizer Pellet Plant Production Line