Grass pellets are pellets that made of grass. Grass is the main food of herbivores, like cattle, horse, rabbit, sheep etc. So, the grass pellets can be used to feed livestock. Compared to grass, grass pellets are convenient for storage and transportation. They contains less dust and debris, are more easy to digest for the animals than common grass.

In fact, grass pellets can also used as fuel for heating if the moisture are accurately controlled. Grass pellets may produce more ash than wood pellets, and the calorie in grass pellets is not so much wood pellets, but the grass pellets are still a well-accepted method in Europe for a long time.

In a word, the grass pellets are an excellent choice for both feed and fuel.

How to make Grass pellets?

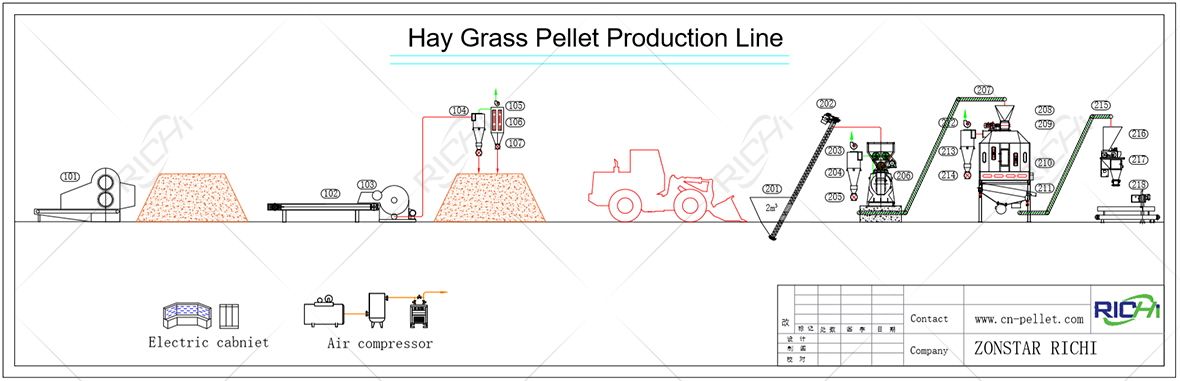

To make pellets for commercial production, you should have a series of associated equipments, like pellet mill, hammer mill, rotary dryer, cooler and packing machine. Form them into a complete line, and then you can produce grass pellets like other biomass pellets.

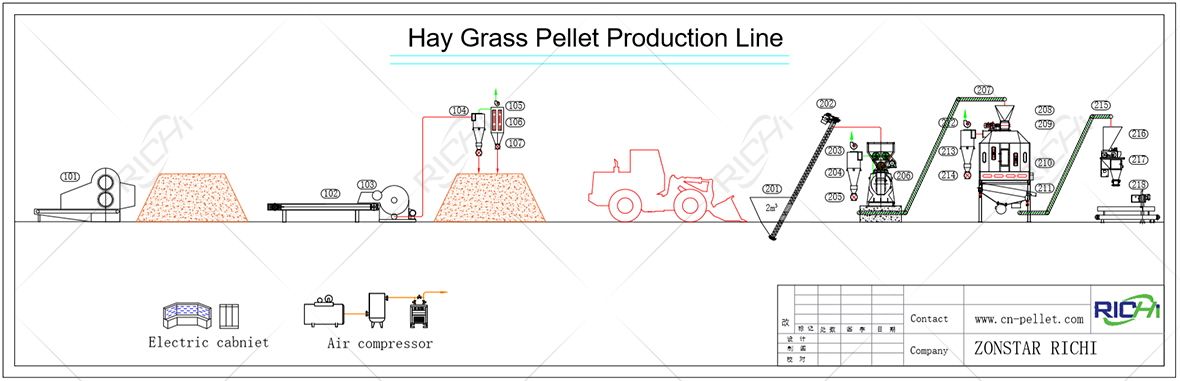

Grass Pellet Plant Production Line Flowchart

- Crushing – Cut the grass into small pieces by a hammer mill. The use of hammer mill can increase greatly the production efficiency.

- Drying – Control the moisture content of grass within a proper range, too high or too low would both influence the density. If the moisture content is too high, you could put grass in a rotary dryer or just in the sun.

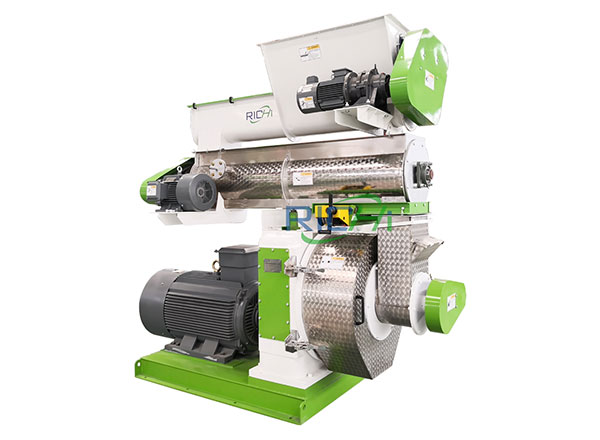

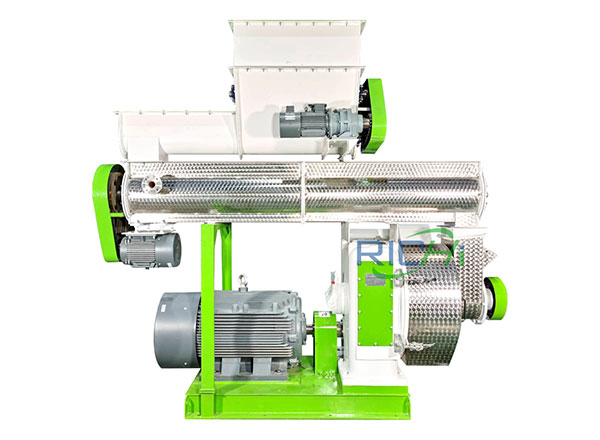

- Pelletizing – Put the grass with proper moisture content into a pellet mill. In the mill, grass would be extruded by die and rollers, and then shaped in pellets at last.

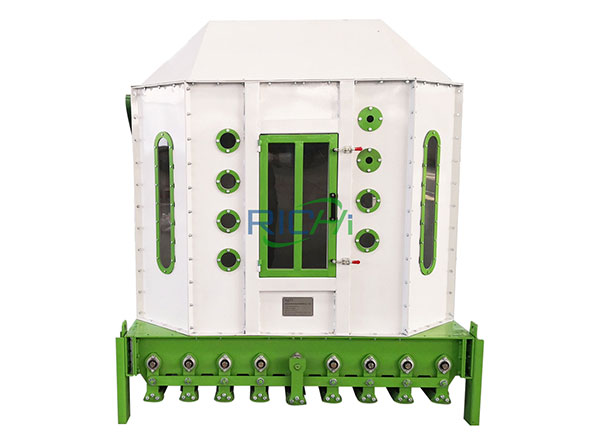

- Cooling – Cool down the grass pellets to room temperature. After getting out of the pellet mill, the temperature of grass pellets is very high.

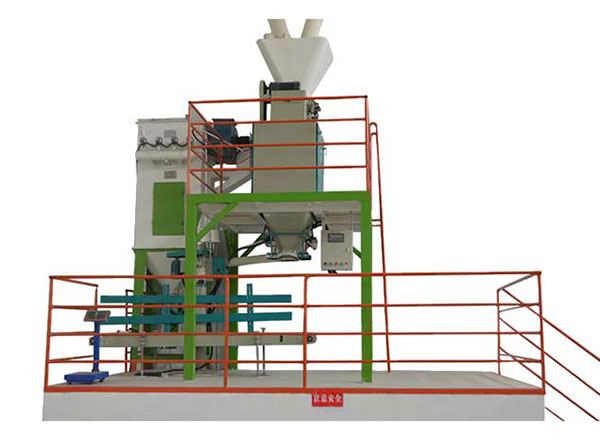

- Packing and Storage – Pack the grass pellets in bags and store them in cool, dry and ventilated locations under normal temperature. Keep them far away from fire, sunshine and rain.

Advantages of grass feed pellets

1. Grass pellet fuels or fodders takes up only one fourth the volume of raw materials, which are much easier for storage and transportation.

2. The compression process reduce the dust contained in grass materials, making the burning more safer and feeding more convenient.

3. Adopting grass pellet fodder is conducive to realize intensive and mechanized production. Pelleting can also improve the fodder quality, making it more suitable for animals eating. Besides, pellets are rich in nutrition and easier to digest.

4. stacks usually have ash deposits. The pellet production can remove the ash and improve the cleanliness of food.

5. is a common animal feed, but it has many defects. supply is rich in summer and short in winter. grasstacks take up too much space. Some grass are too rough to eat directly. Making into pellets can solve these problems.

6. During pellets production, the high temperature and pressure will promote the starch gelatinization in grass, and make it easier for animals to digest. pellets tastes better than grass. Livestock eat more and grow faster.

7. pellets only take up 1/4 the volume of grasstacks, so it can save storage and transportation cost. The feeding process also become simpler, famers can achieve intensive and mechanized husbandry.

Benefits of grass pellets for livestock

High utilization rate and transform rate

As we know that, the growth of the grass is influenced by seasons. When the weather becomes cold, the grass will turn wither with less nutrients. But in the warm season, the grass grow vigorous with more nutrients. To make sure the livestock can get the nutritive feed in winter, we can use the grass pellet mill to transform the grass into grass pellet in the warm season, and store them. Then, in winter, the grass pellet can be fed to the livestock. In addition, the grass pellet fed to the livestock in winter, enable the livestock get more nutrients, so we can gain more meat, and milk.

Storage conveniently

The grass after compressed by the pellet machine turn into grass pellet, its volume is decrease greatly. So that it is convenient to storage and transportation.

Increase palatability and improve quality of the grass

Sweet clover has a special smell, such as the coumarin, so the livestock don’t like eat. But after turn into the coumarin pellet, it becomes the forage with good palatability and high nutrition.

Increase the digestibility

Livestock chew the grass pellet need a longer time, that will improve their mouth secrete more amylase, stimulate the peristalsis of their intestinal and increase the digestibility of the nutriment. In addition, in the process of pressing, the grass pellet after high temperature and high pressure, the material, which will hinder the nutriment be digested, is passivation, that also can increase the digestibility of the forage.

Sterilization and disinfection

In the process of pressing, the grass pellet will go though the short-time heating of 70 ℃ to 100 ℃, that can kill some parasitic ovum, and reduce disease.

Application

Grass pellets are pellets that made of grass. Grass is the main food of herbivores, like cattle, horse, rabbit, sheep etc. So, the grass pellets can be used to feed livestock. Compared to grass, grass pellets are convenient for storage and transportation. They contains less dust and debris, are more easy to digest for the animals than common grass.

In fact, grass pellets can also used as fuel for heating if the moisture are accurately controlled. Grass pellets may produce more ash than wood pellets, and the calorie in grass pellets is not so much wood pellets, but the grass pellets are still a well-accepted method in Europe for a long time.

In a word, the grass pellets are an excellent choice for both feed and fuel.

Investment Guide

| Production Scale |

Project Site Requirements |

Production cycle |

Installation cycle |

Investment Cost(USD) |

Profit cycle |

| 1-2 T/H Feed Pellet Production Line |

300-500m² |

20 Days |

7-15 Days |

10000-50000 |

1-3 Year |

| 3-4 T/H Feed Pellet Production Line |

300-700m² |

20 Days |

15-20Days |

5,0000-12,0000 |

| 5-7 T/H Feed Pellet Production Line |

400-800m² |

20-30 Days |

20-40Days |

7,0000-25,0000 |

| 8-10 T/H Feed Pellet Production Line |

800-2000m² |

30-40 Days |

45-60 Days |

150,000-300,000 |

| 12-20 T/H Feed Pellet Production Line |

1500-3000m² |

40-50 Days |

60-90 Days |

250,000-580,000 |

| 25-40 T/H Feed Pellet Production Line |

2000-4000m² |

50-60 Days |

90-120Days |

45,0000-850,000 |

| 50-60 T/H Feed Pellet Production Line |

3000-5000m² |

60-70 Days |

100-140 Days |

900,000-1,400,000 |

| 60-72 T/H Feed Pellet Production Line |

5000-8000m² |

70-90 Days |

130-160 Days |

1,450,000-1,800,000 |

| 80-100 T/H Feed Pellet Production Line |

8000-20000m² |

90-120 Days |

160 -190Days |

2,000,000-2,800,000 |

About the cost(different types & same capacity):

Poultry Feed Pellet Mill Plant, Ruminant Feed Pellet Mill Line, Livestock Feed Pellet Production Plant, Aquatic Pellet Extruder Plant, Pet Feed Pellet Mill Plant, Premix Feed Processing Plant, Powder Feed Production Line

About the profit :

1. The price of raw materials and feed is different in each country, and the investment cost will fluctuate.

2. The customer's operating costs include site costs, worker wages, and water and electricity costs. Skilled operators can minimize the operating costs of the equipment.

3. The correct management of feed mills, process management and high-quality production line equipment are the basis for the development of feed processing plants and high returns. |