Worldwide bamboo plants are more than 70 genera, about 1,200 species, the total area of about 22 million hm2. Bamboo concentrated in Asia, Latin America, Africa. Most of them grow in tropical and subtropical regions with good monsoon climate and water and heat conditions, a few are grown in temperate and even sub-arctic regions. Southeast Asia monsoon zone (southeastern China, southwestern China, Indochina and the Indian subcontinent) is the world's bamboo distribution center, the region has concentrated 80 percent of the world's bamboo species, 90% of the total bamboo forest area. China, India and Japan are the best countries for bamboo production and bamboo resource development. In European, there is no natural distribution of bamboo species, and the remaining continents are natural distribution, but Britain, France, Germany, Holland and other countries in Europe started the introduction and cultivation of bamboo and grow well.

World Distribution of Bamboo

From a global perspective, based on the geographical distribution of bamboo, three regions are divided - Asia-Pacific bamboo area, American bamboo area and the African bamboo area.

(A) Asia-Pacific bamboo

This area is the world's largest bamboo area, south to south latitude 42°S, north to latitude 51°N, east to the Pacific Islands, west of the southwest Indian Ocean, the distribution of bamboo about 50 genera and 900 species, both bamboo species and bamboo forest area accounts is about 80% of the world's. The south-east of this area is the world's bamboo center of origin, but also one of its modern distribution center. The main bamboo producing countries are China, India, Japan, Myanmar, Thailand, Bangladesh, Cambodia, Vietnam, Laos, Malaysia, Indonesia, the Philippines.

(B) American bamboo

South to south latitude 47°S in southern Argentina, north to latitude 40°N the eastern United States, there are about 18 genera and 270 kinds. In Latin America, Mexico, Guatemala, Costa Rica, Nicaragua, Honduras, Colombia, Venezuela and Brazil, the Amazon Basin in South Tropic of Cancer is the area of bamboo distribution center.

(C) African bamboo

This area has small bamboo range, south to south latitude 22°S in southern Mozambique, north to latitude 16°N in eastern Sudan, a total of about 13 genera and more than 40 kinds. There is few African continent bamboo flora and few native bamboo species, but form a large area of bamboo, or other species associated with the formation of mixed middle and lower classes, while in East Africa, there are 11 genera and 40 kinds in Madagascar, more than the African continent . Within this range, the west coast of Africa south of Senegal, Guinea, Libby Elijah, Southern Ivory Coast, Southern Ghana, Nigeria, Cameroon, Rwanda, Burundi, Gabon, Congo, Zaire, Kenya, Tanzania, Ma Ravi, Mozambique, until the east coast of Madagascar, which is the center of Africa bamboo distribution from northwest to southeast across the tropical rainforests of Africa and the plagioclase zone of evergreen and deciduous forest.

How to make Bamboo pellets?

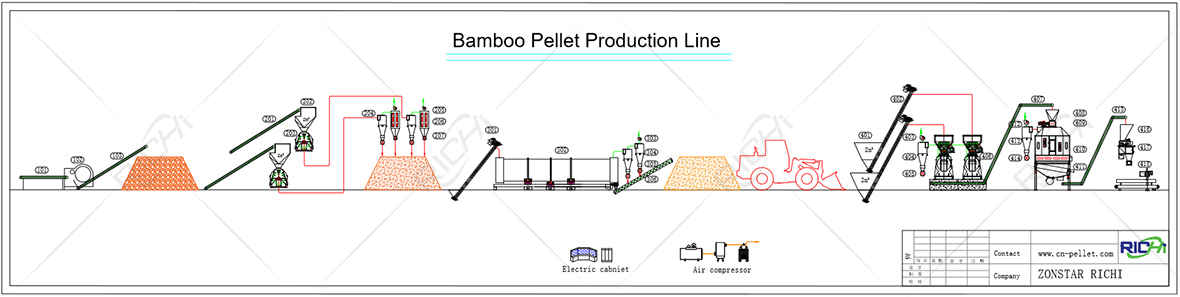

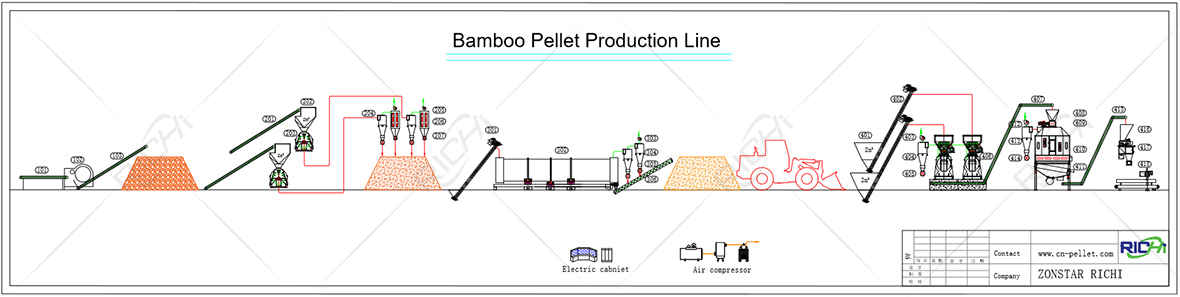

Bamboo Pellet Plant Production Line Flowchart

- Generally speaking, there are some essential pellet equipment you may need in a pellet production line. They are hammer mill, dryer, bamboo pellet mill, counterflow cooler, pellet packing machine.

- Crushing. Screen the bamboo stalks and leaves from the impurities and hard objects, put the pure raw materials into the hammer mill and crush them into bamboo powder.

- Drying. The airflow dryer or the drum dryer can help you to adjust the moisture content of the bamboo powder.

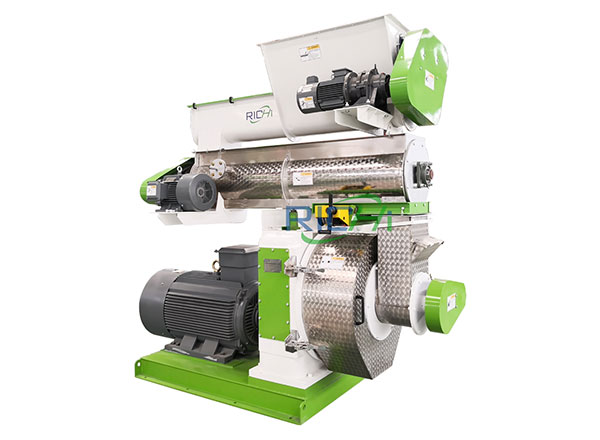

- Pelletizing. A small roller-turned small pellet mill is enough while the ring-die pellet mill can process pellets in larger quantity.

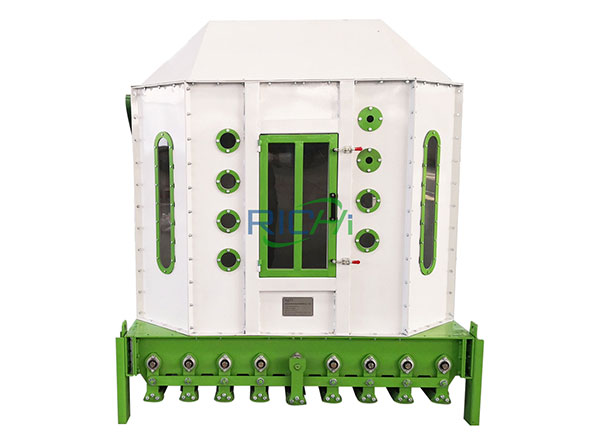

- Cooling. The counterflow cooler can cool the bamboo pellets efficiently. The pellets should be cooled after pelletizing. Or the high temperature pellets can't keep in shape.

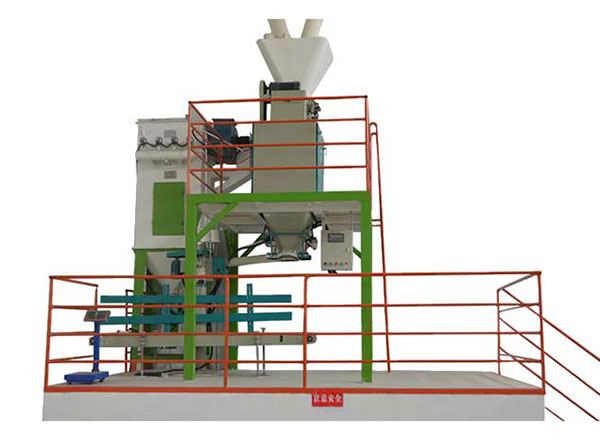

- Packing. After the whole process, you can pack the pellets by a pellet packing machine.

Why Bamboo Pellets Are Popular?

1. High heat value: The heat value of bamboo pellet fuel is as high as 4800 kcal, equal to that of coal but with less space occupation.

2. Low emission: After being handled, bamboo pellets only contain less than 1.1% of ash, which together with little sulfur content contributes to low burning emission, reducing acid rain and green house effect.

3. Wide application: As a kind of novel and green energy form, biomass pellet fuel can be widely used in industrial factory to heat furnace, household to work in stove and service field to supply heat.

4. Easy transportation: Bamboo wood pellet mill makes the final products made in it high in density, which means the volume of them is much smaller compared with the same weight of raw materials. Thus, easy transportation and low delivery fee can be realized.

5. High profits: This money earning method only needs a complete bamboo pellet production line, sufficient supply of raw materials and a few people. In most circumstances, investment will be paid back in several months.

Bamboo Pellet Benefits

- They have as much heat value as coal (around 4800 kcal), and also more compact.

- Bamboo pellets are a source of renewable energy, and are therefore a good alternative to traditional fuel sources like gas or coal. They can cut the cost of such energy sources, including electricity, by up to a half.

- The pellets are light and easy to store. Therefore, their transportation is also easy.

- The bamboo pellets also good for the environment because less than 1 percent of their content ends up being ash. They also have very little emissions as they burn.

- Their breadth of uses is quite impressive. They can heat, cook, and even serve as fuel in steam furnaces.

Other Uses Of Bamboo

1. Culinary Uses

Bamboo is edible after proper processing, They are used in numerous Asian dishes and broths. Pickled bamboo, used as a condiment, may also be made from the pith of the young shoots.In Indonesia, they are sliced thin and then boiled with thick coconut milk and spices to make a dish called gulai rebung. Pickled bamboo shoots are cooked with black-eyed beans as a delicacy in Nepal. In Sambalpur, India, the tender shoots are grated into juliennes and fermented to prepare kardi. This fermented bamboo shoot is used in various culinary preparations, notably amil, a sour vegetable soup.

2. Animal diet

Bamboos make 99 percent of giant panda’s diet, soft bamboo stems, leaves and shoots are rich in sucrose and other sugars. Mountain gorillas also feed on soft bamboo stems and in some cases, some chimpanzees have been seen consuming sap, which is fermented and alcoholic.

3. Kitchenware Uses

The empty hollow in the stalks of larger bamboo is often used to cook food in many Asian cultures. Soups are boiled and rice is cooked in the hollows of fresh stalks of bamboo directly over a flame. In addition, bamboo is frequently used for cooking utensils within many cultures, and is used in the manufacture of chopsticks. In modern times, some see bamboo tools as an ecofriendly alternative to other manufactured utensils.

4. Construction Uses

Bamboo, like true wood, is a natural composite material with a high strength-to-weight ratio useful for structures. In China and India, bamboo was used to hold up simple suspension bridges.

5. Writing pen Uses

In old times, people in India used hand made pens made from thin bamboo sticks by simply peeling them on one side and making a nib-like pattern at the end. The pen would then be dipped in ink for writing.

Investment Guide

We provide customers with cost-effective solutions that are reliable, professional, affordable and add value to their businesses.