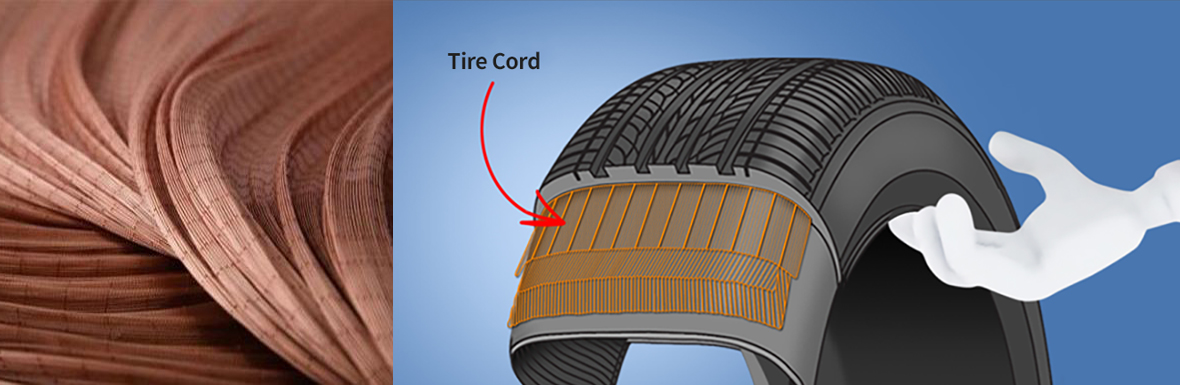

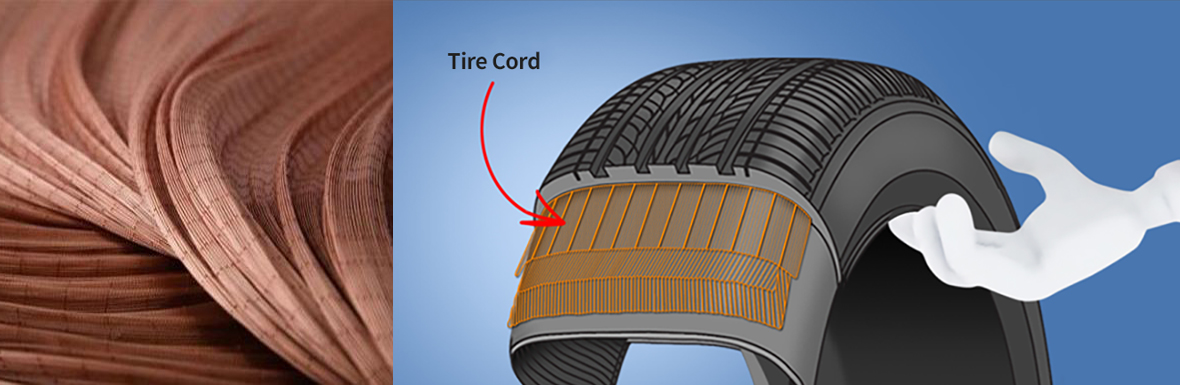

Waste Tire Textile Cord,It is also the first time that I have heard from customers that the cords in used tires can also be compressed into pellets. But we did. This is a customer in Poland, because the raw materials he uses are special, our business manager has communicated with customers many times, and under the technical guidance of our technical engineers. Designed and produced a complete set of pellet production line equipment for this Polish customer. So, no matter what raw materials the customer is, they can communicate with us. Our professional technical engineers will definitely give you a satisfactory solution.

The following is the customer's early consultation content:

Company Recykl O.O. S.A. recycles used tyres and produce so called textile cord. This textile material is composed mainly of polyester fibres and will be pelletized. Company looks for the full pelleting line with capacity of 1 ton of input textile material per hour.

The line should be composed of following components and/or similar granting same function or performance:

1. input bin and feeding of textile material to the conditioner

2. conditioner with ability to add liquid additives and dry powders

3. pelleting machine with pellet diameter 6-8 mm

4. cooling and screening of pellet product

5. packaging – big-bags

6. line operation 365.24 with 70% availability

7. humidity of input material <8%

Please kindly estimate the budgetary price for such a line. The configuration details will be subject of further discussion.

How to Make Waste Tire Textile Cord Pellet?

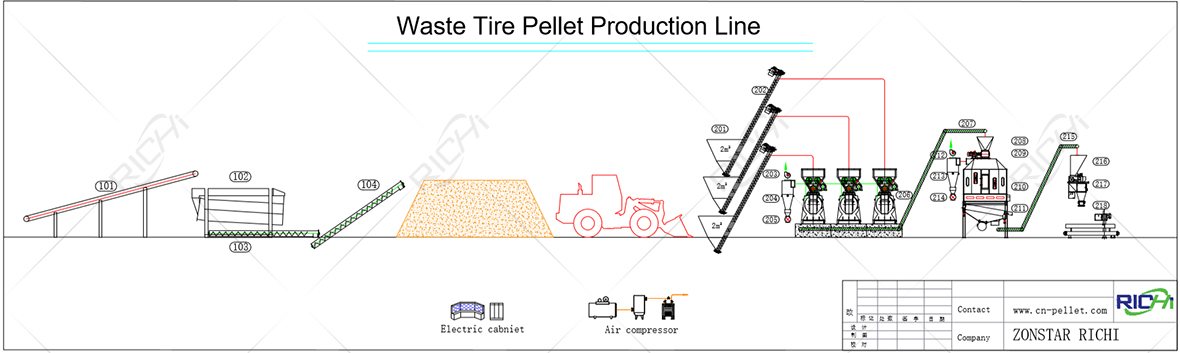

Waste Tire Textile Cord Pellet Plant Production Line Flowchart

Waste Tire Textile Cord Pellet Plant Production Line Flowchart1 – waste tire textile cord crusher can shred waste tire textile cord.

2 – no need dryer: there is no need to use a dryer, because waste tire textile cord contains almost no moisture.

3 – waste tire textile cord fiber hammer mill machine: waste tire textile cord fiber hammer mill machine is designed for crushing the waste tire textile cord fiber into small pieces, and the machine is the necessary equipment for waste tire textile cord fiber pelletizing. Usually the machine can be combined with the waste tire textile cord crusher machine.

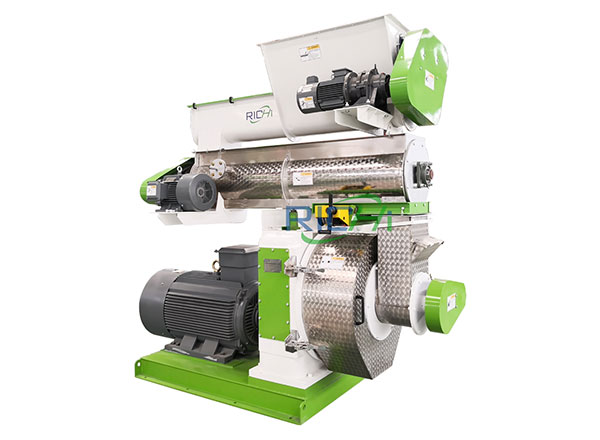

4 – waste tire textile cord pellet machine: generally, the waste tire textile cord pellets production is in large scale. Then our ring die waste tire textile cord pellet machine is the most suitable machine for compressing the high density waste tire textile cord fiber. Adopt high-precision gear driving, the output is improved by about 20% compared with the belt drive one. Imported high-quality bearings and oil seal are adopted to ensure efficient, stable and low-noise operation.

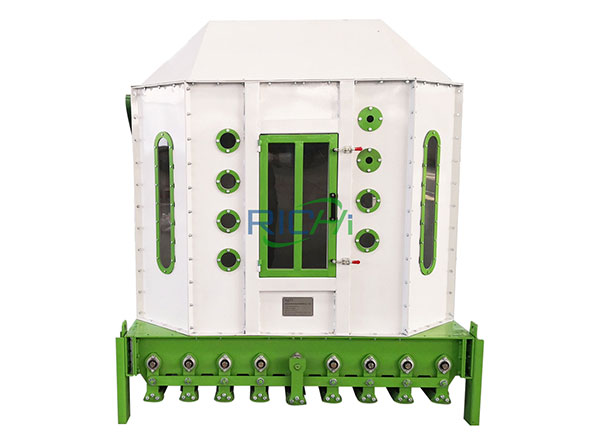

5 – waste tire textile cord pellet cooler: waste tire textile cord pellets discharged from pellet mill are of high temperature about 65℃-90℃ as well as high moisture content of 17%-18%. Pellets will shock if the temperature or humidity is too high. Our counter current pellet cooler is used to remove pellet heat as well as the moisture content to ensure pellets quality and shelf-life.

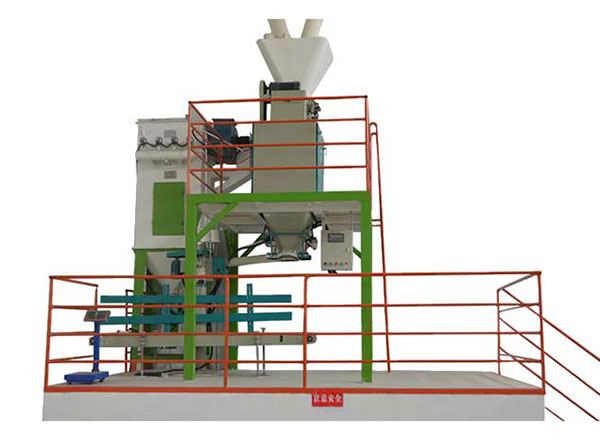

6 – waste tire textile cord pellet packaging machine: after cooling, the packing process is necessary to protect the waste tire textile cord pellet from damp and dust. Automatic waste tire textile cord pellet packing machine is advanced designed and manufactured with plc controlling technology. Equip with accurate measure instrument, it has high weighing precision, bagging speed and stable performance.

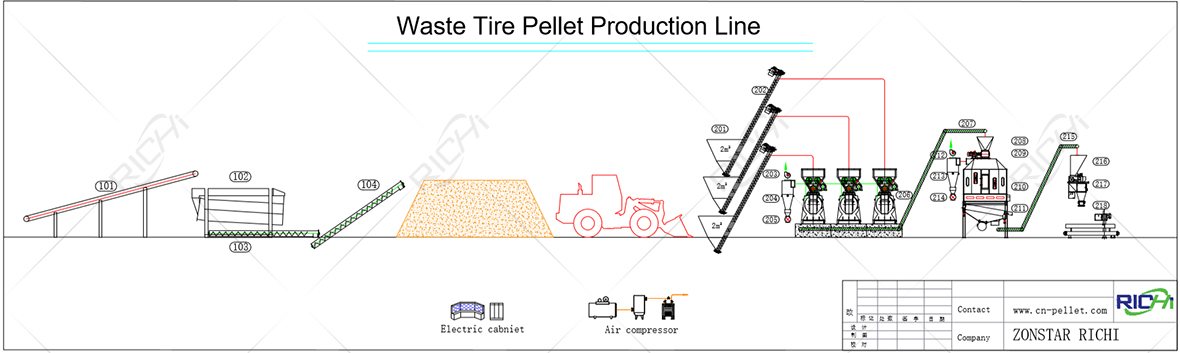

Poland 2-3 t/h Waste Tire Fiber Pellet plant Production Line Project

- Name: Waste Tire Fiber Pellet plant Production Line

- Country: Poland

- Capacity: 2-3 t/h

- Date: Jan 23th,2019

- Installation cycle: 15 Days

- Pellet Size: 6mm pellet

The customer's main raw material is waste tire fiber, and we have designed a targeted plan for the customer's raw material. After more than a dozen design modifications, the Polish client organization experts conducted a review of the Richi design. The expert group believed that the overall program provided by the Richi was superior among the four bidders, with a shorter construction period and lower cost. The customer finally cooperated with our company and set up a Polish project "Technology Group", and designated the technical & installation& coordination chief commander as the staff of Richi.

In this project,workshop size is 26m*4m*8m (L*W*H),total power is 181KW,prime technology equipment include biomass pellet machine*132KW,pellet cooling machine*SKLN14*14,tons of packages scale*LCA-MT,etc.

Investment Guide

We provide customers with cost-effective solutions that are reliable, professional, affordable and add value to their businesses.