Palm fiber is abundant in Malaysia, Serbia, Indonesia, and other Southeast Asia areas, where palm trees are widely planted as a cash crop. Palm fiber are large in size. It contains cellulose and hemicelluloses lignin. Why palm fiber are made into pellets? Can’t we just throw the palm fiber biomass into the palm fiber boilers or palm fiber power plant directly? The reason of converting palm fibers into pellets are as follow: Generally, the energy content of palm fiber biomass will be increased after being converted into pellets. Densified palm fiber pellet fuel or briquettes enjoying a calorific value between 4,200 – 4,900 kg cal/kg 28 can be used to substituted coals to ease energy pressure and environment pressure. palm fiber pellets is sustainable and renewable and can be produced in large scales which also can be friendly to environment. palm fiber pellets are densified and clean and can be easily transported and stored. palm fiber pellets generate little smoke while burning.

How to Make Palm Fiber Pellet?

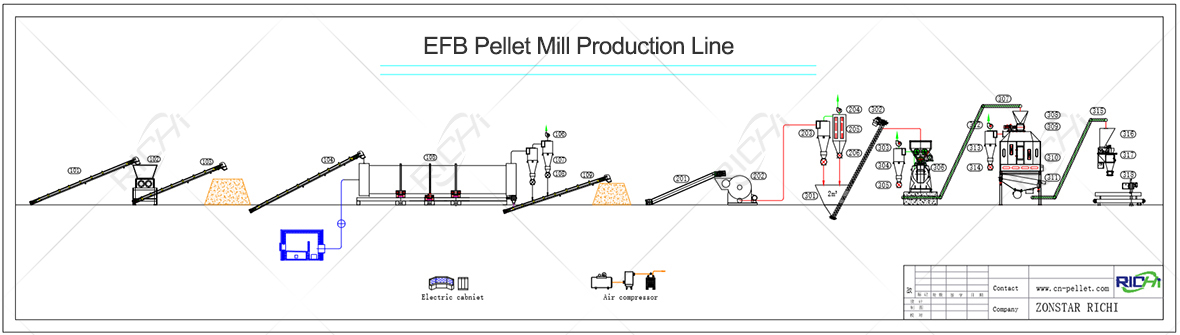

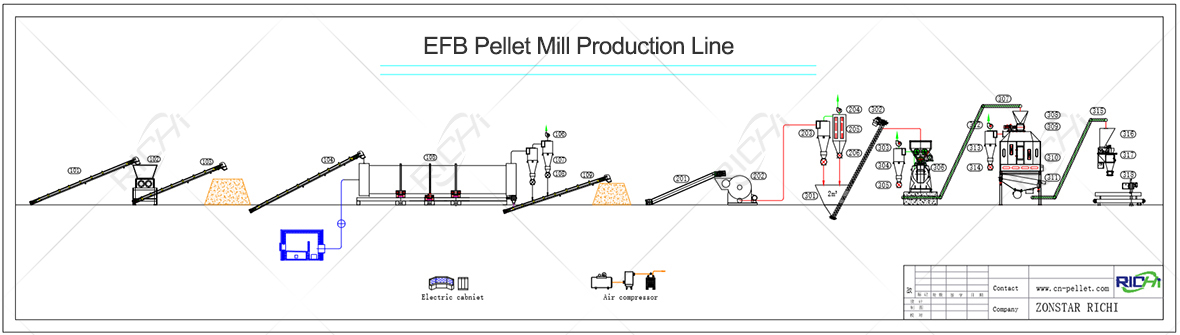

Palm fiber Pellet Plant Production Line Flowchart

Palm fiber Pellet Plant Production Line FlowchartSince the Palm Fiber is large in size and high in moisture content, it will go through a series of processes such as crushing, drying, pelletizing, cooling and packing in order to get the final quality Palm Fiber pellet products.

Step 1 – Palm Fiber Crusher: Palm Fiber crusher is the equipment to process palm fruit bunch into palm fiber, which is easier to be dried and finely crushed in the following processes. Thus the final Palm Fiber pellets quality can be guaranteed.

Step 2 – Rotary Drum Dryer: The proper moisture content for pelletizing is 12-15%, while the moisture content in Palm Fiber is about 67%. Therefore, drying process is necessary for Palm Fiber pellets production. Special designed for drying the Palm fiber, our rotary drum dryer is high in efficiency but low in energy consumption.

Step 3 – Palm fiber Crushing Machine: Palm fiber crushing machine is designed for crushing the Palm fiber into small pieces, and the machine is the necessary equipment for Palm fiber pelletizing. Usually the machine can be combined with the Palm Fiber crusher machine.

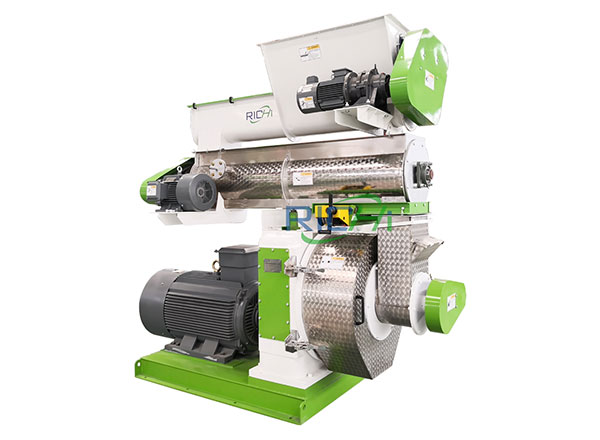

Step 4 – Palm fiber pellet Machine: Generally, the Palm Fiber pellets production is in large scale. Then our ring die Palm Fiber pellet machine is the most suitable machine for compressing the high density Palm fiber. Adopt high-precision gear driving, the output is improved by about 20% compared with the belt drive one. Imported high-quality bearings and oil seal are adopted to ensure efficient, stable and low-noise operation.

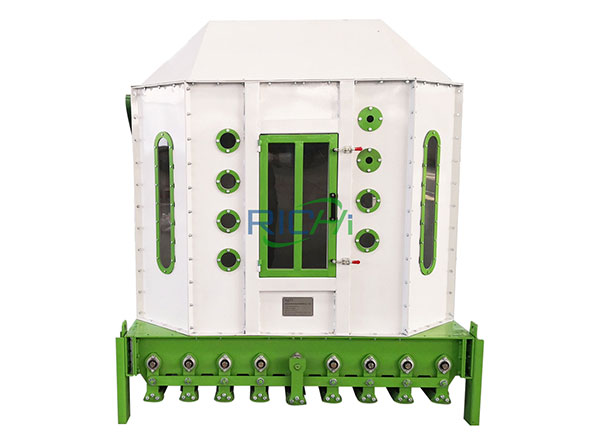

Step 5 – Palm Fiber Pellet Cooler: Palm Fiber pellets discharged from pellet mill are of high temperature about 65℃-90℃ as well as high moisture content of 17%-18%. Pellets will shock if the temperature or humidity is too high. Our counter current pellet cooler is used to remove pellet heat as well as the moisture content to ensure pellets quality and shelf-life.

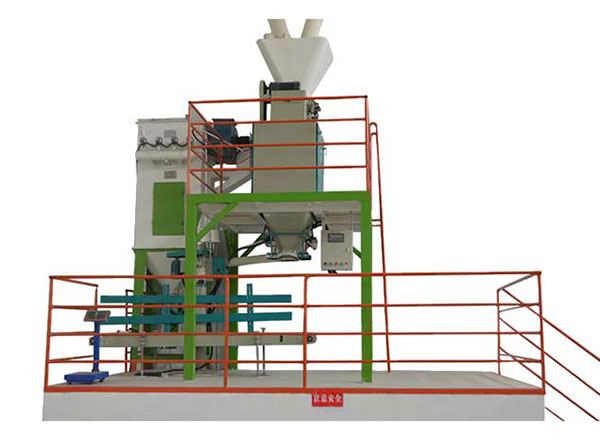

Step 6 – Palm Fiber Pellet Packaging Machine: After cooling, the packing process is necessary to protect the Palm Fiber pellet from damp and dust. Automatic Palm Fiber pellet packing machine is advanced designed and manufactured with PLC controlling technology. Equip with accurate measure instrument, it has high weighing precision, bagging speed and stable performance.

Notes: Raw materials should be sufficient to ensure the continuity of pellet production. So the location of the Palm Fiber pellet plant should be convenient for the raw materials transportation.

All the above processes are equipped with dust collector, which makes the whole process no dust pollution.

Advantages of Palm Fiber Pellets

1. High heating efficiency: the palm fiber pellets can burn sufficiently in the boiler with only 5% ash residues. The calorific value is 4,200 – 4,900 kcal/kg, equivalent to sub-bituminous coal.

2. Low moisture content: palm fiber pellets contains 8-12% or less moisture, much less than palm fiber fibers (50-60%). Low moisture content can improve the combustion ratio and reduce the transportation cost.

3. Wide application: palm fiber pellets can be applied both in home and factory. You can use them in heating stove, cooking range and BBQ, or industrial boiler and power plant to take the place of coal.

4. Environmental friendly: palm fiber pellets emit little smoke, noxious or particles gas in burning.

5. Convenient to use: As palm fiber pellets are much more compact and denser than palm fiber fibers, they need smaller space and loading capacity, therefore less transportation cost.

6. No need for binders: palm fiber contains about 13-25% of lignin and 43-65% of cellulose. The lignin can play the role of binder in pelletizing.

Application

On investing palm fiber biomass pellet production, the following suggestions from successful palm fiber pellet plant investors should be considered:

1. Overall understanding of palm fiber pellet production line is necessary.

2. palm fiber pellet production procedures should meet the requirement of target markets.

3. Raw materials should be sufficient and should ensure the continuity of pellet production.

4. Quality of the raw materials should guaranteed. Raw materials with moisture content of 15%, is ideal while when it goes upper than 15%, the raw materials should be dried.

5. Location of the palm fiber pellet plant should be convenient for raw materials transportation.

6. A feasible survey is necessary to be conducted beforehand.

As for a typical palm fiber pellet production, it should consisted of palm fibers shredding, drying, grinding, pelletizing, cooling, sieving, dust recycling and packing.

Investment Guide

We provide customers with cost-effective solutions that are reliable, professional, affordable and add value to their businesses.