Alfalfa

Alfalfa (Medicago sativa L.) or lucerne is the most important forage legume worldwide and frequently called the ‘Queen of forages’ due to its wide adaptation, high yield, and high quality. This moniker also is due to the fact that it is frequently the most important forage in many regions and is the highest value hay crop in the United States. It is grown from the frozen plains of Southern Canada and Eastern China to the mild climates of Chile’s Central Valley to the searing deserts of Mexico and North and South Africa. It is grown as a highly managed cash crop in irrigated regions, such as California but also as a pasture crop for horses and cattle in midsouthern states, and millions of hectares are grown in Argentina in grazing dairy, beef, and sheep operations. Alfalfa is often the most desired forage for dairy production – it is no accident that the primary alfalfa production regions in the United States correspond with areas of high alfalfa acreage, such as Wisconsin, California, and Idaho.

Alfalfa is widely recognized as the oldest forage plant and remains a dominant and highly desired forage in modern times. It originated in Asia Minor, Iran, and the dry highlands of Turkmenistan, regions of hot, dry summers and well-drained soils, which is why it has been highly successful in similar environments in modern times. Alfalfa is generally used as animal feed pellets, of course, it can also be used as fertilizer pellets and biomass fuel pellets.

How to Make Alfalfa Pellet?

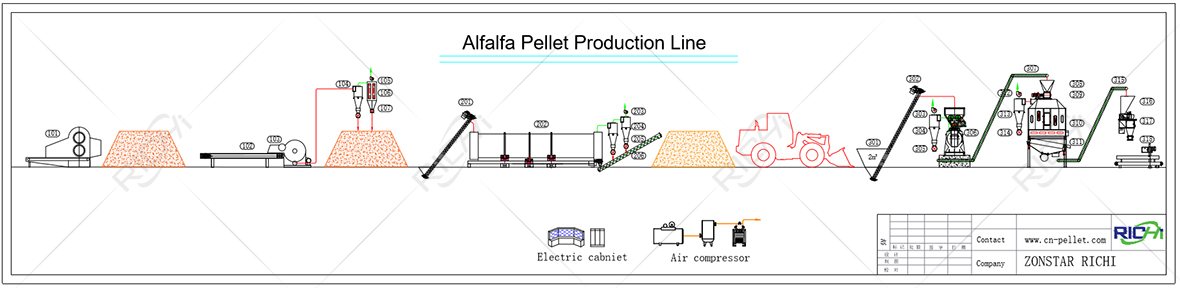

The process of alfalfa pellet manufacturing was first developed for the livestock feed industry. It can be said to consist of a few basic sub-processes: grinding of alfalfa grass, drying, pelletizing and cooling.

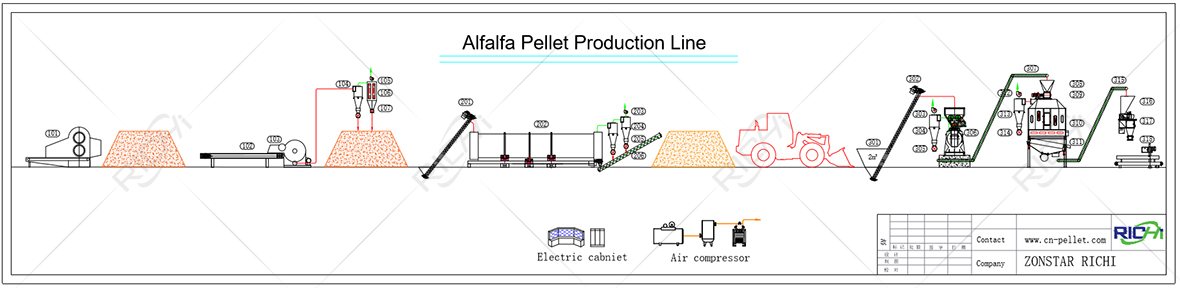

Alfalfa Pellet Plant Production Line Flowchart

- The raw alfalfa grass is first freed from heavy contaminant (rocks, metals and other foreign material), and then grinded in a hammer mill or a chipping machine. The particle size is adjusted to a uniform maximum dimension, which is approximately 85 % or less of the minimum thickness of the pellet to be produced. The often high moisture content of raw alfalfa makes drying necessary. The product from the hammer mill is therefore transported to a dryer (generally a rotary drum type one) where the moisture content of the uniformly dimensioned particles is reduced to about 10 % (w.b.).

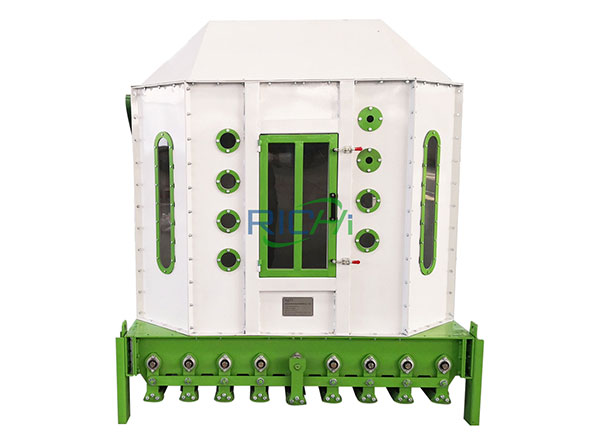

- Then, alfalfa particles can be conditioned, i.e. steam or organic binding agents can be added (according to legal specifications). After conditioning, the particles are then moved by conveyor to a pellet mill, where the pellets are extruded through the action of rollers acting on a perforated matrix. On the outer side of the latter, a knife cut off the pellets at the desired length. Residual moisture in the feedstock turns to steam during compression and helps lubricate the compression die. After extrusion, alfalfa pellets are very hot (90-100°C) and are immediately air quenched down to 25°C. This sets up the lignin and hardens the product, and contributes to maintain its quality during storage and handling.

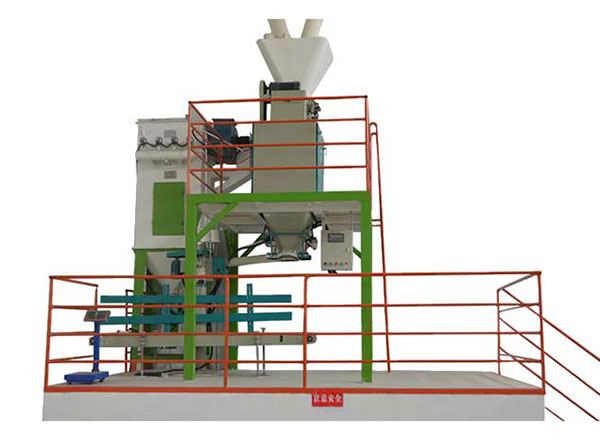

- Finally it is screened, so as to separate the residual fines which are generally re-used in the process. Dust free alflafa pellets are then ready for storage (in a silo) or for automatic packing (in 25 kg bags or big bags – 1 to 1,5 m³).

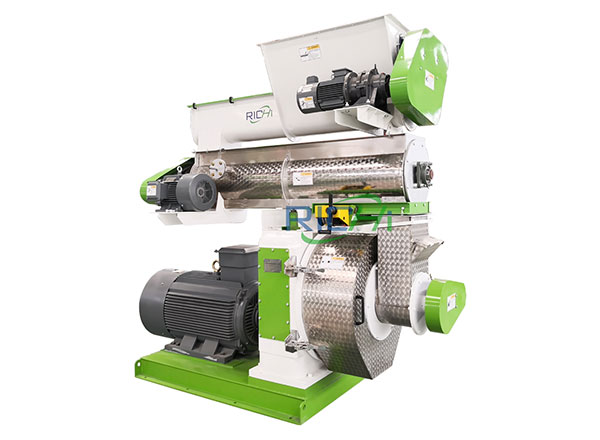

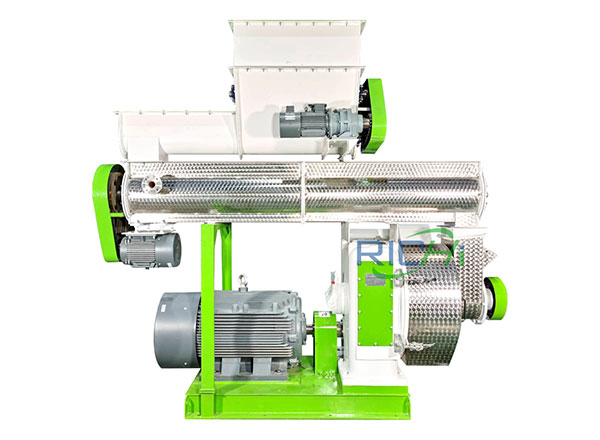

- In the second step in alfalfa pellet processing, there are two main types of pellet presses: flat die and ring die types. The flat die alfalfa pellet machine have a circular perforated disk on which two or more rollers rotate and force the material through the holes. The ring die press features a rotating perforated ring on which rollers (normally two or three) press on the material to the inner perimeter.

- The final processed alfalfa pellets can be used as animal feed, mainly horse feed. Using alfalfa products as forage for animal is very beneficial because it is much more digestible compared to grass hays.

Why Choose Alfalfa For Making Animal Feed Pellets?

- Alfalfa hay is the forage plant par excellence. It has great nutritional properties which makes it the perfect choice for making animal feed pellets.

- High in nutrients: Alfalfa is an excellent source of vegetable protein, energy, vitamins, and minerals for animals including horse, pig and poultry. Besides, it is also rich in many other nutrients such as magnesium, molybdenum, sulfur, boron, calcium, potassium and phosphorus, etc. All these nutrients are good for animal healthy.

- Rich in fiber: For ruminant animals, the fiber in alfalfa is fermentable by the large intestine and their digestibility can be highly improved in this way. The intake of fiber in animal feed is based on the particle size of the feed pellets.

- Good for animals’ healthy: It is found that alfalfa has buffering effects on stomach acid, helping to reduce the incidence and severity of gastric ulcers.

Benefits Of Alfalfa

1. A food source for dairy cows, beef cattle, sheep, horses, and even zoo animals.

2. Legumes such as alfalfa convert atmospheric nitrogen into forms that plants can use.

3. Facilitates soil conservation by reducing soil erosion.

4. A wildlife habitat for hundreds of animals, including some endangered species.

5. Lots of open space is created, which provides beauty.

6. Flowers on the plant make alfalfa honey the main honey crop in the U.S.

7. A habitat for over 1,000 diverse species of insects, spiders, and mites.

Pros and cons of alfalfa pellets

Advantages

Easy to store and transport. Alfalfa pellets have small size and light weigh, and low water absorbency.

Avoid the cattle dietary choosiness, and reduce food waste.

Have good palatability and increase feed intake.

Disadvantages

As we all know, alfalfa has high nutrition, if cattle take too much, after the sun exposure, they will have a higher levels of skin inflammation.

Caused flatulence, especially for the cud chewer like cow or sheep.

Investment Guide

| Production Scale |

Project Site Requirements |

Production cycle |

Installation cycle |

Investment Cost(USD) |

Profit cycle |

| 1-2 T/H Feed Pellet Production Line |

300-500m² |

20 Days |

7-15 Days |

10000-50000 |

1-3 Year |

| 3-4 T/H Feed Pellet Production Line |

300-700m² |

20 Days |

15-20Days |

5,0000-12,0000 |

| 5-7 T/H Feed Pellet Production Line |

400-800m² |

20-30 Days |

20-40Days |

7,0000-25,0000 |

| 8-10 T/H Feed Pellet Production Line |

800-2000m² |

30-40 Days |

45-60 Days |

150,000-300,000 |

| 12-20 T/H Feed Pellet Production Line |

1500-3000m² |

40-50 Days |

60-90 Days |

250,000-580,000 |

| 25-40 T/H Feed Pellet Production Line |

2000-4000m² |

50-60 Days |

90-120Days |

45,0000-850,000 |

| 50-60 T/H Feed Pellet Production Line |

3000-5000m² |

60-70 Days |

100-140 Days |

900,000-1,400,000 |

| 60-72 T/H Feed Pellet Production Line |

5000-8000m² |

70-90 Days |

130-160 Days |

1,450,000-1,800,000 |

| 80-100 T/H Feed Pellet Production Line |

8000-20000m² |

90-120 Days |

160 -190Days |

2,000,000-2,800,000 |

About the cost(different types & same capacity):

Poultry Feed Pellet Mill Plant, Ruminant Feed Pellet Mill Line, Livestock Feed Pellet Production Plant, Aquatic Pellet Extruder Plant, Pet Feed Pellet Mill Plant, Premix Feed Processing Plant, Powder Feed Production Line

About the profit :

1. The price of raw materials and feed is different in each country, and the investment cost will fluctuate.

2. The customer's operating costs include site costs, worker wages, and water and electricity costs. Skilled operators can minimize the operating costs of the equipment.

3. The correct management of feed mills, process management and high-quality production line equipment are the basis for the development of feed processing plants and high returns. |