Cultivation Of Sunflower

Wild sunflower grow naturally in the wild and adapt to areas of fertile soil. Sunflowers grow best in a fertile and well-drained soil. They thrive in slightly acidic to alkaline with a pH value of between 6.0 and 7.5. Being a heavy feeder, sunflower needs a nutrient-rich soil. It also grows well in areas of direct sunlight and prefers long, hot summer to flower well. Sunflower seeds are planted directly in the soil at a spacing of 1.48 feet and 0.98 feet deep. The spacing is necessary to facilitate the branching out of flowers. The small plants require watering regularly to boost their growth and development. Fertilizer can be used sparingly, especially on soils with low fertility level. Tall species and cultivars require support for a short period to enable the flowers to access adequate sunlight. Birds are a threat to the sunflower; therefore they need to be kept away, or the head of the flowers can be covered using clear bags.

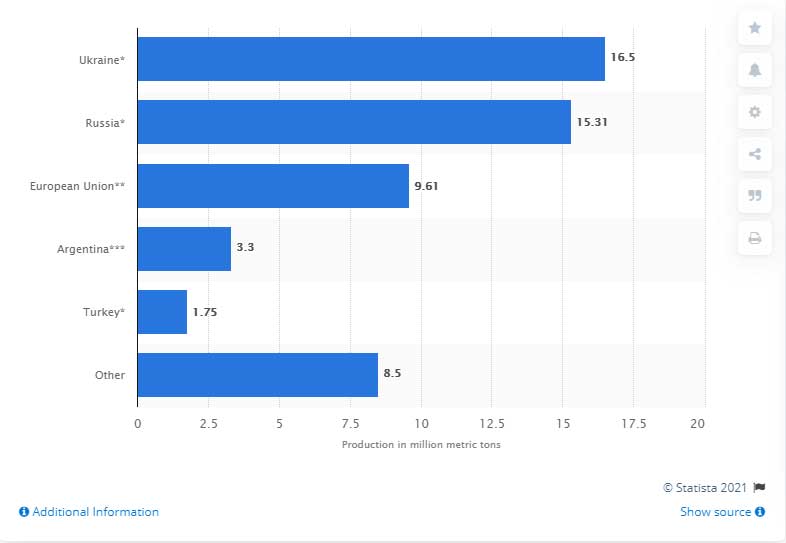

Top Sunflower Seed Producing Countries

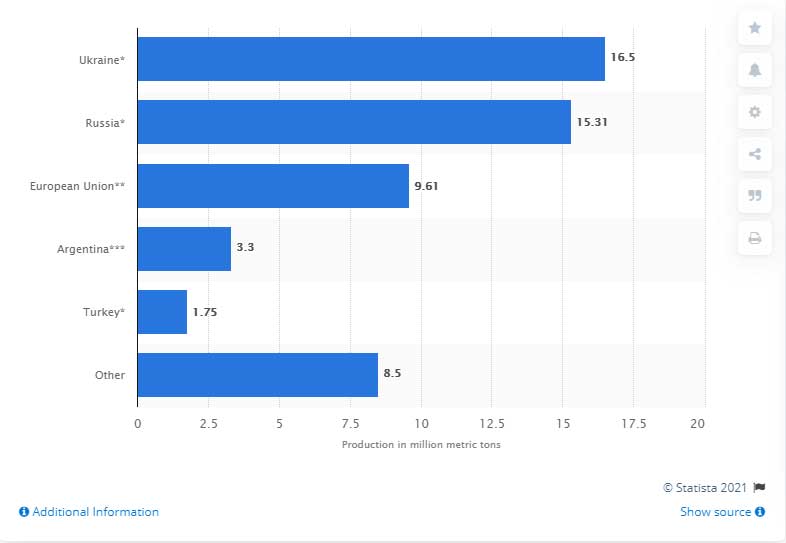

Ukraine and Russia remain the top sunflower seed producers in the world. They produce almost half of the world sunflower seeds. Ukraine produced 16.5 million tons of Sunflower seeds while Russia produced 15.3 million tons in 2019-2020. Argentina, China, Romania, Bulgaria, and Tanzania are also major producers of sunflower seeds in the world.

Production volume of sunflower seed in major producer countries in 2019/2020

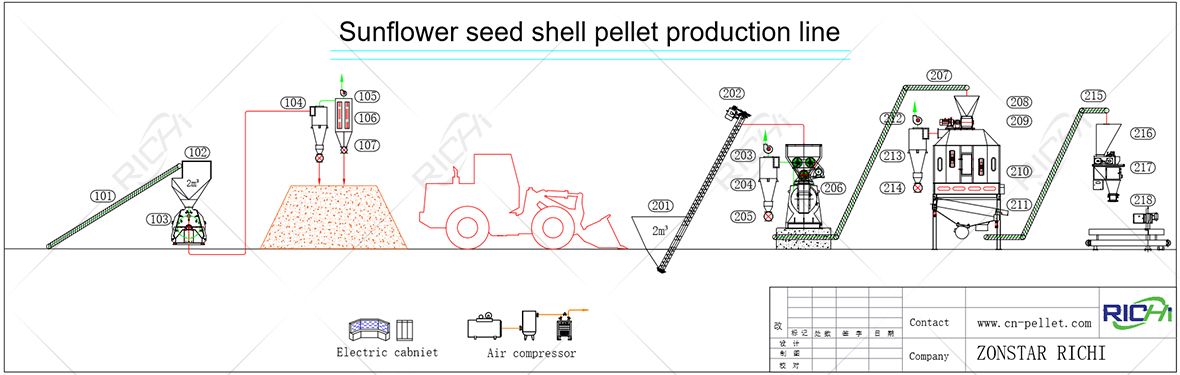

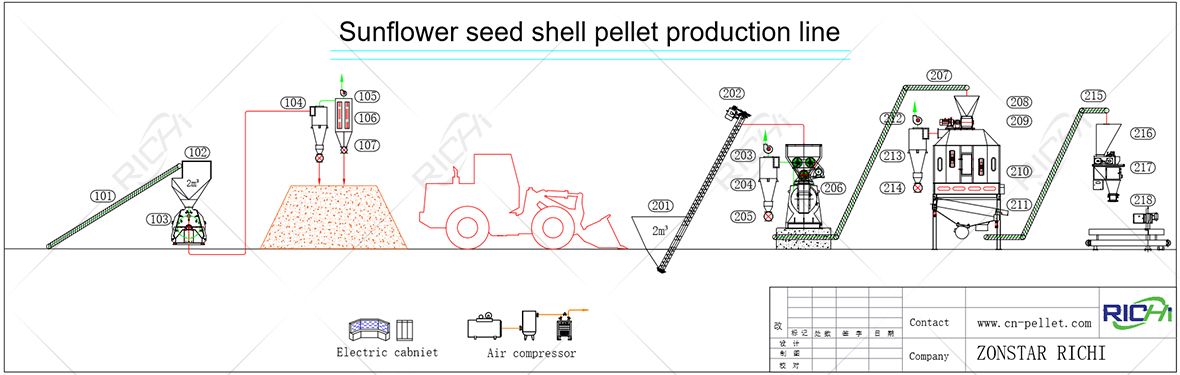

The sunflower seed shell pellet plant production line, also called the melon seeds hull pellet mill production line, can press the crushed and ground biomass wastes including sunflower seeds shell, sun flower tray, sunflower stem, sunflower straw, peanut shell, straw, grass, sawdust, rice husk and tree bark into high density solid granular fuel products which belong to high efficient, green and regenerated energy. These biomass fuel products realize both the energy saving and emission reduction goal and good economic and social benefits.

How to Make Sunflower Seed Shell Pellet?

Sunflower Seed Shell Pellet Plant Production Line Flowchart

1. Crushing process

This process is to crush the sunflower seeds hull into fibrous pieces in order to be better pelletized.

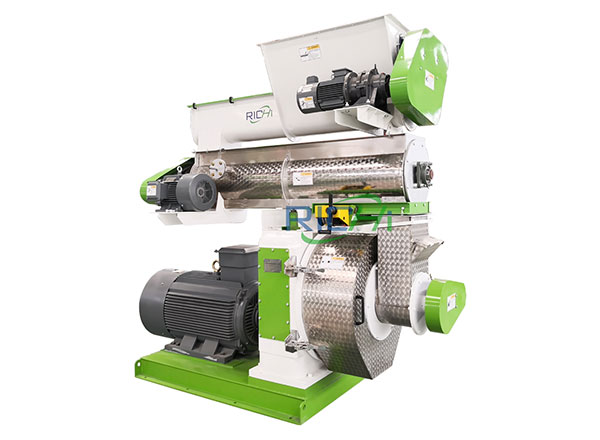

2. Pelletizing process

This process is to grind the fibrous piece to pellet with 6mm,8mm,10mm and 12mm size, which is the core part of the whole production line. Before pelletizing, it needs to pick out iron, stone etc. our company adopts the most advanced ring die sunflower seeds shell pellet machine to pelletize, which features minimum energy consumption, minimum wearing, maximum stress and wide application. What's more, it has lowest sensitivity to different materials.

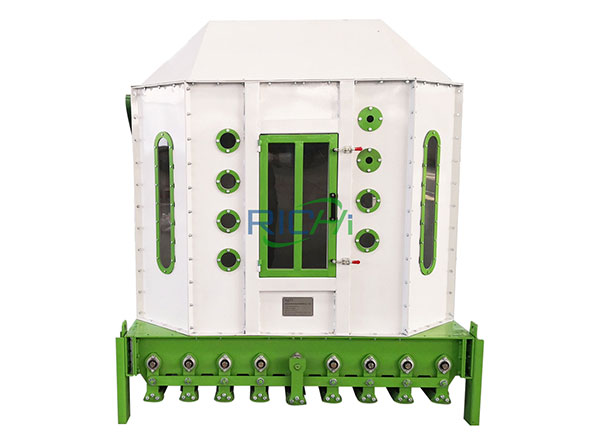

3. Cooling process

The discharged pellets have the temperature of 70-90 degree, which is unable to be packed. The cooling machine will make the temperature reduce to minis or plus 5 degree with room temperature. And then the cooled pellets are packed. This process uses counterflow cooling machine, which features good dust cleaning and short cooling time.

4. Screening process

During pelletizing, cooling and conveying process there will produce some powder for collision. So it needs to use vibrant screening machine to separate the unqualified pellets to achieve the requirement of the packing.

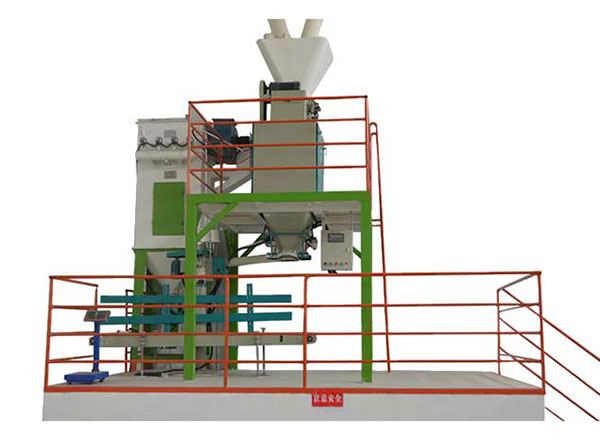

5. Packing process

The final pellets need to be packed, and then sold to customers. It usually uses bags and tons bags. This process packs according to customer's requirement. The packing machine is automatic, which features large capacity, less labor and less packing cost.

Advantages of Sunflower Seed Shell Pellets

These sunflower seed shell biofuel pellets have the following advantages:

- Inexpensive: If compared to other fuels, they are cheaper than gas, coal or fuel oil, therefore they are very efficient if you want a solid fuel.

- Ecofriendly: they are ecofriendly and only release the same CO2 levels as is done when biomass decomposes naturally. That means zero emission of CO2 gas. Plus, no dangerous or cancer-causing material is put out while burning them or storing them.

- Extremely tough, their durability index is 18, and that makes them even harder than an olive cake. Plus, they transport easier and are very uniform in shape and weight.

- High calorific value of 4.3-4.5 kW/kg, which is similar to coal, and is 1.6 times more than wood. When 1,000 kilograms of them are produced, they release the same heat energy as the burning of 685 liters of fuel oil, or five hundred liters of diesel oil or 479 m3 of natural gas, or 1,600 kilograms of wood.

- Sunflower seed shells can now be used to make biofuel mass pellets. These pellets have been used for fuel in power plants in the UK and Poland. They are made by compressing the shells into cylindrical shaped pellets. They range from ten to 30 millimeters long and from six to ten millimeters wide and have a density level of 1.2 kilograms for each 1,000 cubic meters and have eight percent moisture.

Application

1. Fuel: Like other materials for biomass pellet production, sunflower seed shell can also be recycled into fuel which is able to heat the furnace in industrial factory and warm people in their own houses.

2. Animal bedding: Used as animal bedding, sunflower seed hull pellets can provide your poultries or pets with a more comfortable living atmosphere in virtue of their high density and excellent absorbency.

3. Poultry feed: The high carbohydrate and fiber content in sunflower seed shell pellets make them suitable to feed animals, such as horse, cattle, pig and chicken. However, for balanced nutrition, other high-protein fodders should mix together.

Investment Guide

We provide customers with cost-effective solutions that are reliable, professional, affordable and add value to their businesses.