Hotline:+86 18574103366

| |

Model:MZLH

Capacity:0.3 t/h-20 t/h

Applicable: Waste Tire Textile Cord Pellet Maker Plant

This is a customer's patent, using waste tire cords as raw materials, made into biomass particles, and then mixed with concrete to be used for paving roads. The existence of this patent is to reduce road bumps and road light reflection.

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Capacity | 300-400kg/h | 500-700kg/h | 1.0-1.2 t/h | 2.0-2.5 t/h | 2.5-4 t/h | 3-4.5 t/h |

| Pellet Machine Power | 37kw | 55kw | 90kw | 110/132kw | 250/280kw | 280kw |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

| No. | Continent | Country |

| 1 | Europe | Germany, United Kingdom, Netherlands, Spain, Portugal, Albania, Slovakia, Czech Republic, Austria, Poland, Iceland, Ukraine, Romania |

| 2 | America | United States, Canada, Mexico, Brazil, Argentina, Jamaica, Chile |

| 3 | Asia | Thailand, Malaysia, Indonesia, Vietnam, South Korea, China, Pakistan |

| 4 | Africa | South Sudan, Congo (Kinshasa), Zambia, Angola |

| 5 | Oceania | Australia |

Solution

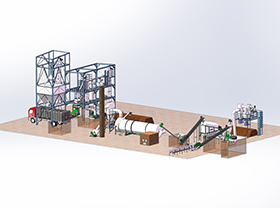

2-2.5 T/H Biomass Wood Pellet Production Line

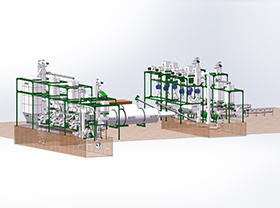

4-5 T/H Biomass Wood Pellet Production Line

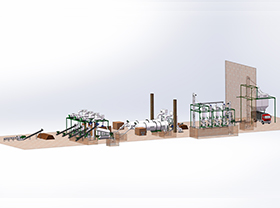

8-10 T/H Biomass Wood Pellet Production Line

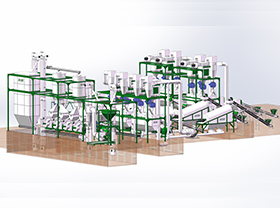

24-30 T/H Biomass Wood Pellet Production Line

Wood Pellet Plant Production Line

Biomass Pellet Plant Production Line

Alfalfa Pellet Plant Production Line

Organic Fertilizer Pellet Plant Production Line