Hotline:+86 18574103366

| |

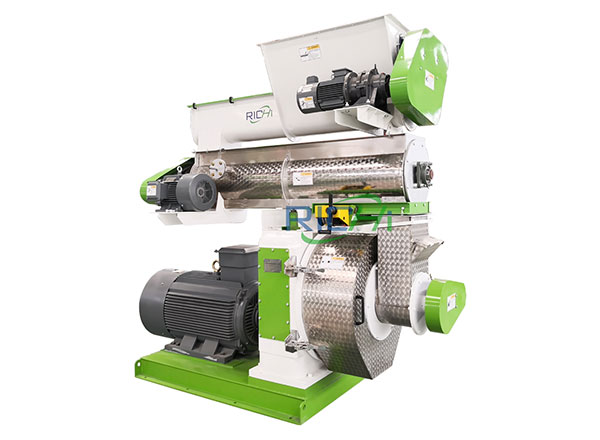

Model:MZLH

Capacity:0.3 t/h-20 t/h

Applicable: Wood Pellet Plant

♦ Level has novel structure, compact, safe and low fault performance.

♦ The host drive with high precision gear drive,the ring die adopt anchorear type and disassembly is convenient.

♦ The Feeder and ring die, the feeding chute adopt stainless steel material,structural durability.

♦ Increase efficiency and high output. High degree of automation, strong applicability. The cutter assembly can control the pellet length.

♦ High quality imported bearings and oil seals are selected in the transmission part of the whole machine to ensure high efficiency, stability and low noise.

♦ The optimized pelletizing chamber structure ensures the that the pressing material is evenly divided and maximizes the working potential of the pelletizer.

♦ Security,has a strong magnetic magnet and overload protection device such as a safe,safe and reliable.

♦ For CE Feeder can let the light raw material to better enter into the pelletizing chamber, and make the pelletizing proCEss normal working

♦ The main drive adopts high-precision gear transmission, and the ring die adopts quick-release hoop type. The output is about 20% higher than the belt drive type.

♦ User-friendly operation , Auto-lubrication system(optional)and die & roller lifting device,energy saving;on-site control.

♦ The variable frequency feeding system adopts the electromagnetic valve speed control, which is convenient for speed adjustment and uniform feeding.

♦ Frequency conversion feeding can be used to effectively prevent the uneven feeding caused by voltage instability.

For large pellet plant, when the raw materials are ready, the first thing to do is raw material size reduction. The raw materials to produce wood pellet must be under the diameter of 5mm, so the logs and branches must be processed into small pieces. In this stage, the large pellet plant usually uses the wood chipper, which is a common size reduction equipment that can cut the wood logs and branches into small wood chips with a diameter no mor than 40mm in order to be further processed. On the contrary, this is not a necessary step for the small pellet plant. If the pellet plant use wood shavings as a raw material, that means the raw materials has already been processed into small pieces in the saw mills, so there is no need to use the wood chippers to cut the raw materials agairn.

For large wood pellet plants, after the initial size reduction step, the raw materials must be dried. In order to produce high quality wood pellets, the raw material must maintains a moisture content of 8% – 12%, so the raw material must be put into a dryer to reduce its moisture content. The most common dryer for large pellet plant is the rotary drum dryer, which is the most cost effective choice for large pellet plant. The drying process is also a necessary step for the small scale pellet plant to produce commercial wood pellet.

For large wood pellet plants, after the drying process, the raw material will be sieved to separate the contaminants such as stone and metal particles away from the wood raw materials. These contaminants may cause the mechanical failure of the pellet mills, so if the raw materials of your pellet plant has the potential to be contaminated by these solid particles, it is necessary for you to sieve the raw materials before fed them into the pellet mill. The machines for the initial sieving process is normally a de-stoner or magnetic separator. Fo small scale pellet plant, due to its limited capital, this is not a necessary step.

Grinding is also a size reduction step to make wood pellet, it is a necessary step for both large and small pellet plants. During the grinding process, the raw materials will be fed into a hammer mill which will grind the raw materials into smaller pieces with a diameter under 5mm. But the hammer mill can only process the wood raw materials with a diameter no mor than 50mm, therefore, the wood logs and branches can not be fed directly into the hammer mill, they must be processed by the wood chipper first.

After the grinding process, the wood raw materials are reached the size and moisture requirements for wood pellet manufacture. Therefore, the following step is to pelletize the raw materials into wood pellet. The machine used to pelletize the raw materials into wood pellet is called pellet mill. There are two kinds of pellet mills, ring die pellet mill and flat die pellet mill. Ring die pellet mill has a capacity over 1ton per hour, it is used for large pellet plant. Flat die pellet mill has a capacity about 500kg per hour, which used for small pellet plant.

After the pelletizing process, the wood pellet is very vulnerable. It has been press over and over in the pellet mill, which makes it hot and easy to be deformed. To make the wood pellet regain its proper rigidity and temperature, the wood pellet will be fed into a pellet cooler right after the pelletizing process. The types of pellet cooler can be divided into three types, the horizontal cooler, the vertical cooler and the counter flow cooler. All of them can be used to cool the wood pellet, but the counter flow cooler is my recommendation, as it is the most advanced pellet cooler in the market.

At this stage, the wood pellet sieving purpose is different from the initial sieving. This step only exist in the commercial wood pellet plant. As the commercial wood pellet has a strict limit on fine content, therefore, after the pellet cooling process, the wood pellet products will be sieved in order to separate the fine particles from the well made wood pellet. For the final sieving process, the vibrating screen is a common equipment for wood pellet plant.

The economic advantages of wood pellets are striking: Compared to fossil oil or natural gas, you can save about half of your expenses on fuel.

An important factor for the cost-effectiveness of wood pellet heating are the highly efficient heating devices that were developed for this solid fuel. Wood pellet central heating boilers, as well as wood pellet stoves, transform more than 90 % of the energy contained in the fuel into usable heat. Essentially, it is this combination of low fuel costs and efficient heating devices that makes the use of wood pellets so cost-effective.

Investment in a new heating system is expensive and therefore should be profitable in the long run. Severe rise in prices and unpredictable risks characterize the market for fossil fuels. In comparison, the supply of wood from domestic forests is much more secure and less volatile. Austria produces more wood pellets solely as by-products of timber processing than are consumed in the country.

Wood pellets have a decided advantage over fossil fuels: They are produced from renewable materials such as wood shavings and saw dust. Austria is among the most richly forested countries in Europe. Over 30 million solid cubic meters of wood grow each year. The timber stock in Austrian forests has been increasing for years despite intensive use for construction timber, paper manufacturing and as an energy source.

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Capacity | 300-400kg/h | 500-700kg/h | 1.0-1.2 t/h | 2.0-2.5 t/h | 2.5-4 t/h | 3-4.5 t/h |

| Pellet Machine Power | 37kw | 55kw | 90kw | 110/132kw | 250/280kw | 280kw |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

| No. | Continent | Country |

| 1 | Europe | Germany, United Kingdom, Netherlands, Spain, Portugal, Albania, Slovakia, Czech Republic, Austria, Poland, Iceland, Ukraine, Romania |

| 2 | America | United States, Canada, Mexico, Brazil, Argentina, Jamaica, Chile |

| 3 | Asia | Thailand, Malaysia, Indonesia, Vietnam, South Korea, China, Pakistan |

| 4 | Africa | South Sudan, Congo (Kinshasa), Zambia, Angola |

| 5 | Oceania | Australia |

Solution

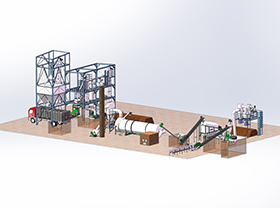

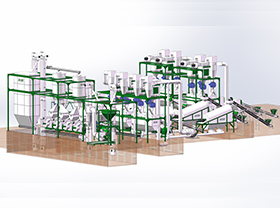

2-2.5 T/H Biomass Wood Pellet Production Line

4-5 T/H Biomass Wood Pellet Production Line

8-10 T/H Biomass Wood Pellet Production Line

24-30 T/H Biomass Wood Pellet Production Line

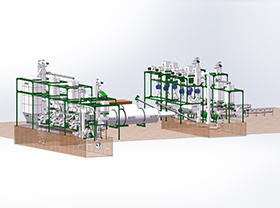

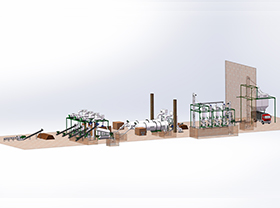

Wood Pellet Plant Production Line

Biomass Pellet Plant Production Line

Alfalfa Pellet Plant Production Line

Organic Fertilizer Pellet Plant Production Line