Hotline:+86 18574103366

| |

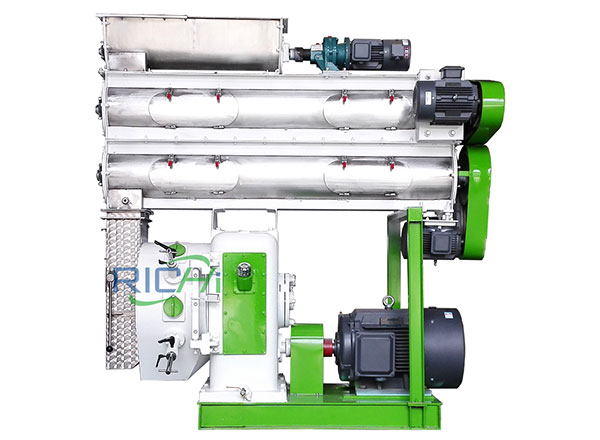

Model:MZLH

Capacity:0.3 t/h-20 t/h

Applicable: Cat Litter Pellet Mill Plant

The idea of a substance designed to soak up cat urine is nothing new. During the early 20th century, people used everything from ash to sand to address the problem, with varying degrees of success, but cats aren’t all that enamored with these particularly harsh substances, and both have a tendency to stick to feet and fur, which causes cleaning headaches around the home.

During the 1940s, Edward Lowe discovered that granulated clay absorbed moisture and trapped bad odors, but crucially, cats didn’t track the clay through the house afterwards. Lowe recommended the solution to his friends, and the feedback he received was universally positive.

Lowe spotted a business opportunity. He filled five-pound bags with his granulated clay, and branded it “kitty litter.” This relatively simple solution to an age-old problem was an instant hit, and made Lowe rich beyond his wildest dreams.

Cat box fillers made from absorbent clay account for approximately 95% of all cat litter. Clay, a naturally-occurring, nonmetallic substance, is composed of a combination of aluminum silicates and minerals. Light-colored clays are more popular than the darker clays because the latter tends to become muddy when wet and cannot absorb additional moisture.

Although most commercial cat box fillers use an absorbent clay as their base, any-thing that can absorb moisture theoretically can be used as cat litter.

Wood

Recycled waste products from the lumber industry are used to make alternative cat litter. A blend of cedar chips and hardwood, for example, is lighter than clay-based litters, and its cedar scent absorbs litter box odors. Another type is made from the waste products of aspen lumber. In this manufacturing process, the sawdust and bark are finely ground, then heated to 1200°F (649°C) in a kiln-type vat. This causes the resin or tree sap to bind the wood together as the material is extruded through a screen to form quarter-inch pellets. The pellets are then passed through a cooling tank on a covered conveyor before they are packaged.

Paper

The natural absorbency of paper makes it a viable alternative to traditional cat box fillers. To produce paper litter, post-consumer newspaper is re-pulped, de-inked, and screened. During the re-pulping process, long fibers are processed back into paper, but short fibers are considered waste. The short fibers are de-watered, pelletized, dried, combined with an odor-control agent, and packaged as cat litter. Like those made from wood, paper litter is also lightweight, about 40% less than clay-based litters. This paper-based litter is also flushable in small quantities.

Grain

The byproducts of hard grains are also used as alternative cat litter. The manufacturer mills hard grains, similar to those used to make pasta, to a consistency required for mixing and pelletizing. Fragrance, small pieces of corncob, and sometimes catnip are added. An advantage to grain products is that the enzymes in the mixture naturally neutralize the cat's waste odors.

Corncobs

Recycled corncobs can be made into pellets for use as cat litter. During the manufacturing process, the light outer portion and the

Odor-control, tracking, and dust are three areas of concern for cat litter manufacturers. Many companies experiment with different ingredients and test out the litter on their own cats before selling it to pet owners.

Odor-control, tracking, and dust are three areas of concern for cat litter manufacturers. Many companies experiment with different ingredients and test out the litter on their own cats before selling it to pet owners.

spongy center are ground, heated, and processed into pellets, which are reground and screened. Compared to the same volume of clay product, the material weighs about half as much and is five times as absorbent. Other advantages are that the litter clumps and is flushable.

Citrus

Recycled waste from the citrus fruit industry makes fresh-smelling cat box fillers. The manufacturer takes peels of de-juiced citrus fruits, presses them, and dries them in natural gas-fired kilns. A screening process removes the dust and fine pieces from the final product. Citrus cat litter is highly absorbent, flushable, and biodegradable. In addition, the residual citric acid in the dried peel naturally neutralizes waste odors.

GrassFinally, cat litter has been made from northern red wheat straw grasses. Bales of straw are ground and chopped into tiny pieces before they are pelletized. The pellets are vacuumed twice to remove dust and then packaged. The resulting product is biodegradable.

Clumping cat litter, easy to clean. When the cat has finished defecating, cat owners can use the shovel after using the clumping of cat litter shovel out of the cat litter box, do not have to throw away the whole box of cat litter.

Bentonite cat litter, high hardness, water absorption quickly, easy to clean, cat owners can not put it into the toilet to wash away.

Tofu cat litter is not as hard as bentonite cat litter, but it has strong odor absorption ability. Tofu cat litter is soluble in water and cat owners can flush down the toilet after use.

Fewer people use clumping pine cat litter, generally more people use non-clumping pine cat litter. It has the advantage of dust-free, cat owners can use the cat litter as flower fertilizer, you can also flush it into the toilet.

One ton of sugarcane can produce about 300kg bagasse. The production of sugarcane bagasse per year in Brazil is 75~90 million tons. About 90% or more is used as fuel to supply power for factory. With wood pellets making machine, bagasse can be extruded into pellets fuel.

Some sugar mill owners sell their excess sugarcane bagasse pellets to other factories with boilers or export them to foreign countries. Recently many East Asian countries such as China have started imported large quantities of sugarcane bagasse pellets. An average size power plant usually consumes over 10,000 tonnes of sugarcane bagasse pellets every month.

With feed pellet mill, through high pressure and high temperature processing, bagasse can be used as animal feed instead of grass and other fodder materials. Bagasse feed pellets can mainly be used to feed cattle, cows, sheep, fish and so on.Years of experiments show that adding 38%~40% puffed bagasse in forage does good to animals’ healthy. The experimental data is as below:

In countries such as India, China, Colombia, Iran, Thailand and Argentina, bagasse is used in lieu of wood to create paper and pulp. Bagasse has good qualities for creating paper for mass production and distribution. It is also used to create thicker material boxes and boards as a substitute for plywood. Many companies even use it to build furniture.

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Capacity | 300-400kg/h | 500-700kg/h | 1.0-1.2 t/h | 2.0-2.5 t/h | 2.5-4 t/h | 3-4.5 t/h |

| Pellet Machine Power | 37kw | 55kw | 90kw | 110/132kw | 250/280kw | 280kw |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

| No. | Continent | Country |

| 1 | Europe | Germany, United Kingdom, Netherlands, Spain, Portugal, Albania, Slovakia, Czech Republic, Austria, Poland, Iceland, Ukraine, Romania |

| 2 | America | United States, Canada, Mexico, Brazil, Argentina, Jamaica, Chile |

| 3 | Asia | Thailand, Malaysia, Indonesia, Vietnam, South Korea, China, Pakistan |

| 4 | Africa | South Sudan, Congo (Kinshasa), Zambia, Angola |

| 5 | Oceania | Australia |

Solution

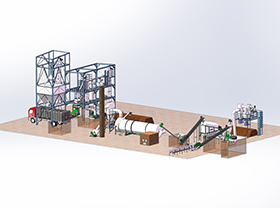

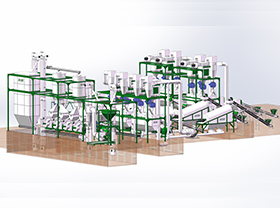

2-2.5 T/H Biomass Wood Pellet Production Line

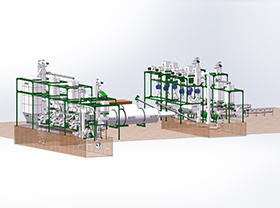

4-5 T/H Biomass Wood Pellet Production Line

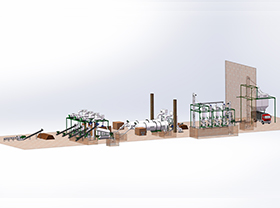

8-10 T/H Biomass Wood Pellet Production Line

24-30 T/H Biomass Wood Pellet Production Line

Wood Pellet Plant Production Line

Biomass Pellet Plant Production Line

Alfalfa Pellet Plant Production Line

Organic Fertilizer Pellet Plant Production Line