Hotline:+86 18574103366

| |

Model:MZLH

Capacity:0.3 t/h-20 t/h

Applicable: Grass Pellet Plant

1. The growth and utilization of the fodder are greatly influenced by seasons. Forage turn wither and yellow with less nutrients in winter . Yet, forage grow vigorous with more nutrients so that livestock can’t eat them up in warm seasons. So, in order to make full use of grass in the warm season to make the effect to come true, the livestock and poultry can be fed in winter with the grass pellets conserved in process of mowing, drying, crushing. For instance, sweet clover possesses a flavor of coumarin which livestock more or less don’t like it. However, it becomes another forage with a a strong palatability and high nutritional value.

2. High transform rate. Feeding the livestock and poultry with the grass feed pellets in winter, we can gain more meat, egg and milk with less forage.

5. To spread the source of fodder

4. To increase palatability and improve the quality of forage.

3. Small volume. Grass pellet is only around 1/4 of the raw materials in volume in favorable for storage and transportation. In addition, less dust is beneficial to the health of human and animals. Such as caragana, optimal quinoa, hedysarummaxim. Etc which have the thick branches turn to the favorable forage once processed into the grass pellets after crushing. Moreover, secondary product of other crops such as abortive shell, straw as well as all kinds of leaves also can be processed into grass pellets and feed livestock and poultry.

Green grass-like granules with alfalfa as the main raw material and pressed by a granulator are 20㎜-30㎜ in diameter and 6㎜-8㎜ in diameter. The density is 600-1200㎏ / m3, which is 2 to 2.05 times that of loose grass powder. Can reduce the contact area with air, reduce oxidation, and facilitate transportation and storage. Feeding objects: cattle, sheep, rabbits and other fish.

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Capacity | 600-800kg/h | 800-1000kg/h | 1.5-2t/h | 3-4 t/h | 5-7 t/h | 8-10t/h |

| Pellet Machine Power | 37kw | 55kw | 90kw | 110/132kw | 250/280kw | 280kw |

| Final Pellet | 1-12mm | 1-12mm | 1-12mm | 1-12mm | 1-12mm | 1-12mm |

| No. | Continent | Country |

| 1 | Europe | Germany, Britain, Russia, Ukraine, Netherlands, Belgium, Slovenia, Bosnia and Herzegovina, Poland, Lithuania, Moldova, Romania, Spain, Albania, Slovakia, Czech Republic, Austria |

| 2 | America | United States, Mexico, Colombia, Canada, Chile, Bolivia, Ecuador, Trinidad and Tobago, Dominica, Bahamas, Puerto Rico, Honduras, El Salvador, Panama, Peru, Brazil, Argentina, Jamaica |

| 3 | Asia | Uzbekistan, Russia, Kazakhstan, China, Vietnam, Cambodia, Myanmar, Thailand, Malaysia, Canada, Indonesia, Philippines, Sri Lanka, Bangladesh, Nepal, Oman, Cyprus, Syria, Lebanon, Palestine, Pakistan, Israel, Iraq , Saudi Arabia, Yemen, UAE, Qatar, Afghanistan, Georgia, Bahrain |

| 4 | Africa | Algeria, Ethiopia, Kenya, Tanzania, Nigeria, Zimbabwe, Botswana, South Africa, Comoros, Malawi, Mozambique, Sudan, Tunisia, Libya, South Sudan, Somalia, Rwanda, Uganda, Mauritania, Senegal, Gambia, Guinea , Cape Verde, Sierra Leone, Ghana, Benin, Côte d’Ivoire, Burkina Faso, Madagascar, Cameroon, Equatorial Guinea, Congo (DRC), Zambia, Angola |

| 5 | Oceania | Australia, Papua New Guinea, New Zealand |

Solution

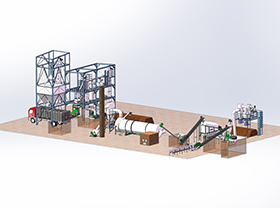

2-2.5 T/H Biomass Wood Pellet Production Line

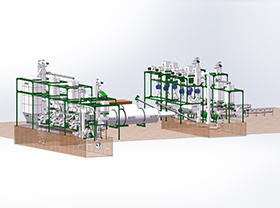

4-5 T/H Biomass Wood Pellet Production Line

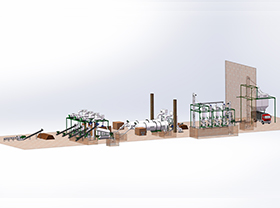

8-10 T/H Biomass Wood Pellet Production Line

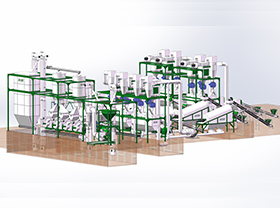

24-30 T/H Biomass Wood Pellet Production Line

Wood Pellet Plant Production Line

Biomass Pellet Plant Production Line

Alfalfa Pellet Plant Production Line

Organic Fertilizer Pellet Plant Production Line