Hotline:+86 18574103366

| |

Model:SZLH-678D

Capacity:20-30T/H

Applicable: animal feed making plant and pet food plant

The SZLH678D 15-25 t/h feed pellet mill maker is one of the indispensable equipment in the feed plant. It can be used alone or in the 15-25 t/h feed pellet production line. The feed pellet maker machine can make various animal feeds: aquatic feed, such as fish feed, shrimp feed, crab feed; poultry feed, such as chicken feed, duck feed, goose feed, bird feed; livestock feed, such as horse feed, pig feed Feed, rabbit feed; ruminant feed, such as cattle feed, sheep feed, camel feed; pet food, such as pet dog food, cat food, hamster food, etc.

Richi machinery large commercial new technology SZLH678D 15-25 t/h feed pellet mill maker is high precision gear drive ring die feed pellet machine, this machine has stainless steel conditioner, with frequency speed control, use “SKF” high quality bearing, ensure high-efficiency, stable and low noise drive, can work alone with its electric cabinet. It can used in all kinds of large and middle farms to make feed pellet to feeding animals, for raw materials, it can be grain, such as wheat, corn, maize, etc.,and some grass, straw also can be applied to this machine,has a very broad application.

| No. | Continent | Country |

| 1 | Europe | Germany, Britain, Russia, Ukraine, Netherlands, Belgium, Slovenia, Bosnia and Herzegovina, Poland, Lithuania, Moldova |

| 2 | America | United States, Mexico, Colombia, Chile, Bolivia, Ecuador, Trinidad and Tobago, Dominica, Bahamas, Puerto Rico, Honduras, El Salvador, Panama, Peru |

| 3 | Asia | Uzbekistan, Russia, Kazakhstan, China, Cambodia, Myanmar, Thailand, Malaysia, Canada, Indonesia, Philippines, Sri Lanka, Bangladesh, Nepal, Oman, Cyprus, Syria, Lebanon, Palestine, Pakistan, Israel, Iraq, Saudi Arabia Arabia, Yemen, UAE, Qatar, Afghanistan, Georgia, Bahrain |

| 4 | Africa | Algeria, Ethiopia, Kenya, Tanzania, Nigeria, Zimbabwe, Botswana, South Africa, Comoros, Malawi, Mozambique, Sudan, Tunisia, Libya, South Sudan, Somalia, Rwanda, Uganda, Mauritania, Senegal, Gambia, Guinea , Cape Verde, Sierra Leone, Ghana, Benin, Côte d’Ivoire, Burkina Faso, Madagascar, Cameroon, Equatorial Guinea, Congo (DRC), Zambia, Angola |

| 5 | Oceania | Australia, Papua New Guinea, New Zealand |

| No. | Continent | Country |

| 1 | Europe | Germany, Britain, Russia, Ukraine, Netherlands, Belgium, Slovenia, Bosnia and Herzegovina, Poland, Lithuania, Moldova |

| 2 | America | United States, Mexico, Colombia, Chile, Bolivia, Ecuador, Trinidad and Tobago, Dominica, Bahamas, Puerto Rico, Honduras, El Salvador, Panama, Peru |

| 3 | Asia | Uzbekistan, Russia, Kazakhstan, China, Cambodia, Myanmar, Thailand, Malaysia, Canada, Indonesia, Philippines, Sri Lanka, Bangladesh, Nepal, Oman, Cyprus, Syria, Lebanon, Palestine, Pakistan, Israel, Iraq, Saudi Arabia Arabia, Yemen, UAE, Qatar, Afghanistan, Georgia, Bahrain |

| 4 | Africa | Algeria, Ethiopia, Kenya, Tanzania, Nigeria, Zimbabwe, Botswana, South Africa, Comoros, Malawi, Mozambique, Sudan, Tunisia, Libya, South Sudan, Somalia, Rwanda, Uganda, Mauritania, Senegal, Gambia, Guinea , Cape Verde, Sierra Leone, Ghana, Benin, Côte d’Ivoire, Burkina Faso, Madagascar, Cameroon, Equatorial Guinea, Congo (DRC), Zambia, Angola |

| 5 | Oceania | Australia, Papua New Guinea, New Zealand |

| Model | Capacity(TPH) | Main Motor Power(kw) | Feeder Motor Power(kw) | Conditioner Power(kw) | Dia.of Ring Die(mm) | Final Pellet(mm) |

| SZLH678 | 20-30 | 220/250 | 2.2 | 11 | 678 | 2~12 |

| SZLH678D | 15-25 | 200/220/250 | 2.2 | 11 | 673 | 2~18 |

Puerto Rico 1200-1500 KG/H High Quality Fish Feed Pellet Mill Plant Project

Country: Puerto Rico

Capacity: 1200-1500 KG/H

Iraq Good Stability 1-2 T/H Chicken Feed Pellet Mill Machine Production Line

Country: Iraq

Capacity: 1-2 T/H

Samarkand, Uzbekistan Good Quality 3-5 T/H Animal Feed Pellet Mill Line Project

Country: Samarkand, Uzbekistan

Capacity: 3-4T/H

Solution

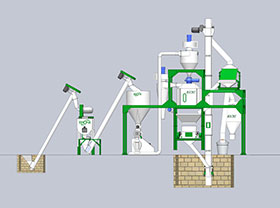

Easy to Operate 1-2 T/H Feed Pellet Production Line

Good Feedbacke 5-7 T/H Feed Pellet Production Line

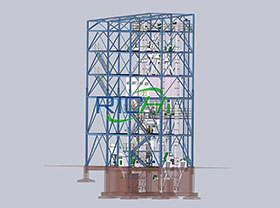

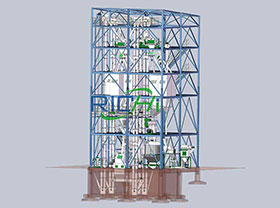

Good Quality 8-12 T/H Feed Pellet Production Line

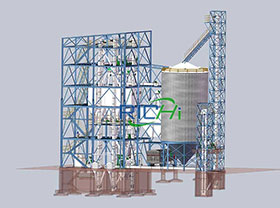

High Performance 20-30 T/H Feed Pellet Production Line

Shrimp Feed Pellet Plant Production Line

Poultry Feed Pellet Plant Production Line

Ruminant Feed Pellet Plant Production Line

Livestock Feed Pellet Plant Production Line