Hotline:+86 18574103366

| |

Model:MZLH-858

Capacity:10-12 t/h

Applicable: organic fertilizer pellet making plant

| No. | Category | Raw materials list |

| 1 | Agricultural waste | straw, dregs of beans, cotton dregs, rice bran, biogas waste, mushroom waste, etc. |

| 2 | Animal waste | slaughterhouse waste, fish market waste, urine and dung of chicken, pig, cattle, sheep ducks, geese, goat, etc. |

| 3 | Industrial waste | wine lees waste, vinegar waste, manioc waste, sugar waste, etc. |

| 4 | Home waste | food waste, bones, the roots and leaves of vegetables, etc. |

| 5 | Mineral | humic acid, bentonite, dolomite, etc. |

| 6 | Sludge | river sludge, pond sludge, sewage sludge, city sludge, etc. |

Because of the organic matter present in organic fertilizer, soil structure is improved and as a result the soil’s ability to hold onto water and nutrients increases.

Synthetic fertilizers runoff into our waterways harming marine life and water quality. Organic fertilizers do not run off as easily (if at all) and are associated with soil structure. According to the Organic Trade Association, organic fertilizer also increases species biodiversity by 30% compared with synthetic fertilizer.

Although organic fertilizer can be more costly than synthetic, it can reduce the need for pesticides and the overall nitrogen, phosphorus and potassium requirements. Because of the reductions, organic fertilizer can be cost neutral and sometimes a cost savings.

Synthetic fertilizer consists of chemical molecules without carbon. These molecules can sometimes be disruptive and are not accessible to microbes. On the other hand, organic fertilizer is rich in organic matter, which helps microbes thrive. Organic fertilizer contains carbon as part of its chemical makeup; and it is the carbon, along with nitrogen, phosphorus and potassium that feeds microbes and enables them to make nutrients available for plants in a naturally occurring biological process.

Vegetable growth

Fruit growth

Viticulture

Arboriculture

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Capacity | 1-2t/h | 3-4 t/h | 5-6 t/h | 7-8 t/h | 9-10 t/h | 10-12t/h |

| Pellet Machine Power | 37kw | 55kw | 90kw | 110/132kw | 250/280kw | 280kw |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

Solution

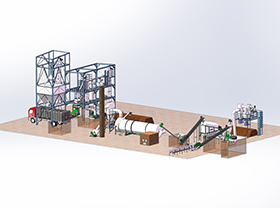

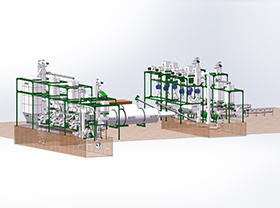

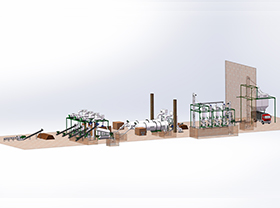

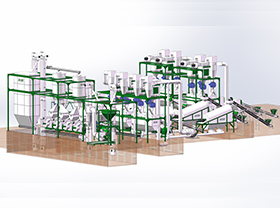

2-2.5 T/H Biomass Wood Pellet Production Line

4-5 T/H Biomass Wood Pellet Production Line

8-10 T/H Biomass Wood Pellet Production Line

24-30 T/H Biomass Wood Pellet Production Line

Wood Pellet Plant Production Line

Biomass Pellet Plant Production Line

Alfalfa Pellet Plant Production Line

Organic Fertilizer Pellet Plant Production Line