Hotline:+86 18574103366

| |

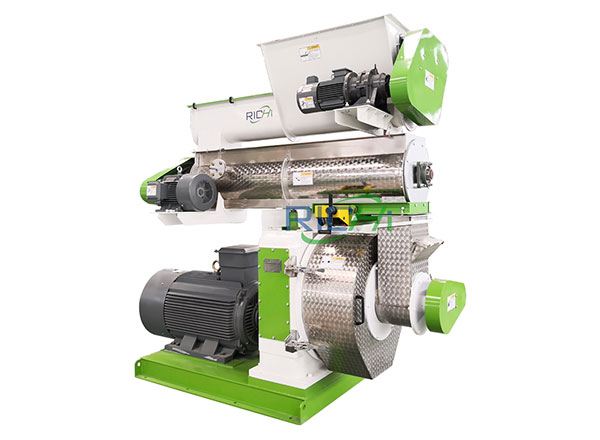

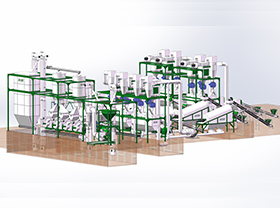

Model:MZLH-768

Capacity:2.5-4 t/h

Applicable: wood biomass pellet making plant

As a substitute for fossil fuel, biomass energy plays an important role in social life. Wood pellets emerge as the time requires, finally gaining favor from people around the world. Increasing demand pushes up the price, so more and more people choose to make wood pellets with their own pellet mills. Wood pellets have such irreplaceable advantages. The biomass pellet are used in large-scale power plants, medium-scale district heating systems, and small-scale residential heat.

Richi Machinery high capacity fully automatic MZLH768 2.5-4 t/h wood biomass pellet mill pelletizer is suitable for the materials with low adhesive and formation rate, which are difficult to pressing molding, such as rice husk, sunflower seed husk , peanut hull, a variety of wood wast like branch, trunk, bark, various of crop straw, eucalyptus, paim fiber(EFB), coffee shell, sawdust and so on.

Many facts and scientific research departments such as the Pellet Fuels Institute has proved that wood pellets can be used circularly, they are made from wood scraps or other organic matters.

Want to make wood pellets, wood pellet machine is necessary, which can provide lots of jobs to local labors, and improve the development of economy. So wood pellets not only can be used as biofuels, but also are welcomed by the government.

Compared with other fossil fuels, wood pellets have competition in economic cost due to the features of itself. They will cost less and save a lot of money compared to coal, natural gas and so on.

It is easy to pack the pellets into bags for storage or transportation because the size of the wood pellets is small and uniform. Generally any size of bags can be put into wood pellets according to your real situation. Sometimes, we make many wood pellets once, and can’t use up. Under the circumstance, wood pellets are much easier to storage than raw materials. When you want to use them, you can directly take them out and pour into your stoves conveniently.

Wood pellets are made by pellet machines, compared the raw materials like wood chips or sawdust so on, the moisture content is low and calorific value is high. So this can reduce the cost of purchasing raw materials as biofuel.

When burning, wood pellets will release carbon natural gas, not harmful to the environment, so wood pellets are green and sustainable energy source. It is environmental.

| No. | Continent | Country |

| 1 | Europe | Germany, Britain, Russia, Ukraine, Netherlands, Belgium, Slovenia, Bosnia and Herzegovina, Poland, Lithuania, Moldova |

| 2 | America | United States, Mexico, Colombia, Chile, Bolivia, Ecuador, Trinidad and Tobago, Dominica, Bahamas, Puerto Rico, Honduras, El Salvador, Panama, Peru |

| 3 | Asia | Uzbekistan, Russia, Kazakhstan, China, Cambodia, Myanmar, Thailand, Malaysia, Canada, Indonesia, Philippines, Sri Lanka, Bangladesh, Nepal, Oman, Cyprus, Syria, Lebanon, Palestine, Pakistan, Israel, Iraq, Saudi Arabia Arabia, Yemen, UAE, Qatar, Afghanistan, Georgia, Bahrain |

| 4 | Africa | Algeria, Ethiopia, Kenya, Tanzania, Nigeria, Zimbabwe, Botswana, South Africa, Comoros, Malawi, Mozambique, Sudan, Tunisia, Libya, South Sudan, Somalia, Rwanda, Uganda, Mauritania, Senegal, Gambia, Guinea , Cape Verde, Sierra Leone, Ghana, Benin, Côte d’Ivoire, Burkina Faso, Madagascar, Cameroon, Equatorial Guinea, Congo (DRC), Zambia, Angola |

| 5 | Oceania | Australia, Papua New Guinea, New Zealand |

| Model | Capacity | Pellet Machine Power | Anti-caking Feeder Power | Forced Feeder Power | Final Pellet |

| MZLH768 | 2.5-4 t/h | 250/280kw | 3KW | 1KW | 6~12 mm |

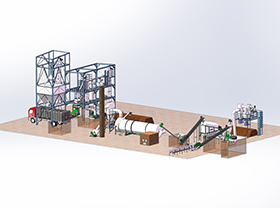

Germany Factory Price Good Stability 2-2.5 T/H Wood Sawdust Pellet Production Plant

Country: Germany

Capacity: 2-2.5 T/H

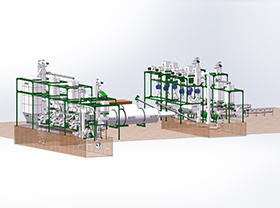

Australia Competitive Easy to Operate 2-2.5 Tph Wood Pellet Making Plant

Country: Australia

Capacity: 2-2.5 T/h

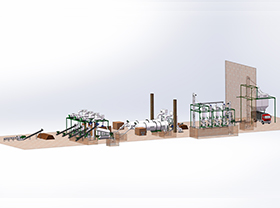

Austria 5 T/H Large Scale Wood Sawdust Pellet Plant Production Line Project

Country: Austria

Capacity: 5 T/H

Solution

2-2.5 T/H Biomass Wood Pellet Production Line

4-5 T/H Biomass Wood Pellet Production Line

8-10 T/H Biomass Wood Pellet Production Line

24-30 T/H Biomass Wood Pellet Production Line

Wood Pellet Plant Production Line

Biomass Pellet Plant Production Line

Alfalfa Pellet Plant Production Line

Organic Fertilizer Pellet Plant Production Line