Hotline:+86 18574103366

| |

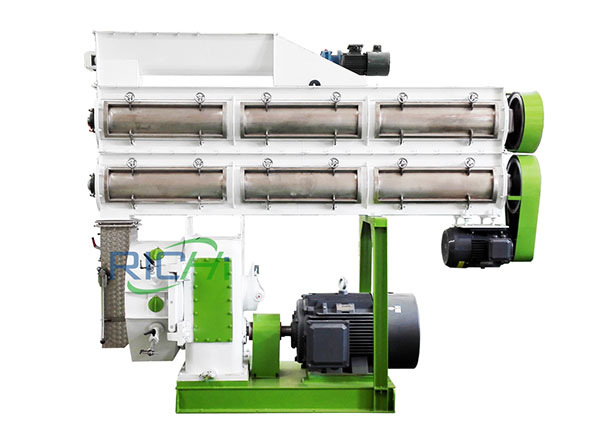

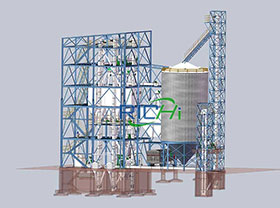

Model:SZLH

Capacity:1-40T/H

Applicable: rabbit feed producing plant

Rabbits due to their unique digestive systems, rabbits require a diet that’s high in fiber, low in protein. The basic nutritional needs of rabbits are carbohydrates, proteins, fats, fiber, vitamins, minerals and water, thus the nucleus of any good rabbit diet consists of pellets, fresh hay, water, and fresh vegetables. Treats, such as fruits or prepared rabbit snacks, are acceptable but should be used very sparingly and in small quantities. It’s important for your rabbits’ health and longevity that you commit to feeding it a proper diet.

Rabbit pellets have long been considered the base of a rabbit’s diet. But pellets are actually more important in the younger stages of rabbit development than in adult rabbits. If you want to invest in a rabbit feed factory, you need to buy a rabbit feed pellet machine. Richi Machinery professional easy to use rabbit pellet feed making machine compact structure, excellent workmanship, easy operation, long life, is a very cost-effective pelletizing equipment.

1. Juvenile rabbits

Corn 30%, bean cake 23%, wheat bran 12%, rice bran 10%, grass meal 20%, bone meal 2%, salt 0.5%, feed 10 grams-20 grams per rabbit per day, and supplement 50 grams-100 grams of green feed.

2. Adult rabbits

Early stage: corn 10%, green hay 7%, bean cake 5%, wheat bran 10%, table salt 2%, feed 120g-150g per rabbit per day, appropriate amount of green fodder. Later period: corn 80%, green hay 10%, wheat bran 5%, bone meal 3%, salt 2%, free intake is implemented, and green fodder is appropriately fed every day.

3. Breeding male rabbits

Non-breeding period: 15% corn, 11% bean cake, 20% wheat bran, 50% grass meal, 2% salt, 100 grams per rabbit per day, plus 700-800 grams of green material. Breeding period: corn 11%, bean cake 25%, wheat bran 20%, grass meal 40%, bone meal 2%, salt 1.5%, 150g-200g per rabbit per day, 700g-800g green feed.

4. Empty pregnant female rabbit

Corn 15%, bean cake 25%, wheat bran 10%, rice bran 10%, grass meal 35%, bone meal 3%, salt 1.5%, 150 grams per rabbit per day, 800 grams-1000 grams of green material, plus earthworm 3 -5 articles.

(1)Transportation economy.

After pelletization, the bulk density of the feed generally increased, which reduces the storage capacity and saves transportation costs.

(2)Avoid picky eaters.

The compound Rabbit feed formula has a variety of raw materials and is comprehensive in nutrition, which prevents the animal from picking up the favorite food from the powder and refuses to ingest other ingredients. Feeding loss can reduce because the pellet feed maintains uniformity during storage and feeding.

(3)High rate of return.

In the pelletizing process, due to the combined action of water, temperature and pressure, some physical and chemical reactions occur in the feed, gelatinization of the starch, and enhanced activity of the enzyme, which enables the animals to digest the feed more efficiently and transform into an increase in body weight. Feeding poultry and Rabbits with pellet feed improves feed conversion compared to Rabbit powder feed.

(4)Sterilization.

Salmonella in animal feed. Salmonella retained in animal tissues when it is ingested by animals. Animal who eat this bacteria will get Salmonella gastrointestinal problems. The method of re-granulation by steam high-temperature quenching and tempering can kill the presence of Salmonella in animal feed.

(5)Reduce pollution.

Avoid automatic grading of feed ingredients. In the powder storage and transportation process, due to the different volume and quality of various powders, it is easy to produce classification. After the pellets formed, there is no classification of the feed ingredients, and the pellets are not easy to dust, and the particulates have less air and moisture pollution than the powder during the feeding process.

(6)Good liquidity.

Easy to manage. Many powders, especially velvet feeds with a small specific gravity, often add molasses or high fat and urea feeds to the stock. Due to the good fluidity of the feed pellets, there is little sticking, and for those farms that use automated feeders to raise cows or poultry on a large scale, pellet feed is the most popular.

| Model | Capacity(TPH) | Main Motor Power(kw) | Feeder Motor Power(kw) | Conditioner Power(kw) | Dia.of Ring Die(mm) | Final Pellet(mm) |

| SZLH250 | 1-2 | 22 | 0.75 | 1.5 | 250 | 2~12 |

| SZLH320 | 3-4 | 37 | 1.5 | 2.2 | 320 | 2~12 |

| SZLH350 | 5-7 | 55 | 1.5 | 3 | 350 | 2~12 |

| SZLH420 | 8-12 | 110 | 1.5 | 7.5 | 420 | 2~12 |

| SZLH508 | 10-18 | 160 | 2.2 | 11 | 508 | 2~12 |

| SZLH558 | 15-25 | 180/200 | 2.2 | 11 | 558 | 2~12 |

| SZLH558D | 14-22 | 160/180/200 | 1.5 | 7.5 | 558 | 2~18 |

| SZLH678 | 20-30 | 220/250 | 2.2 | 11 | 678 | 2~12 |

| SZLH678D | 15-25 | 200/220/250 | 2.2 | 11 | 673 | 2~18 |

| SZLH768 | 25-40 | 280/315 | 2.2 | 11 | 768 | 2~12 |

| SLZH858 | 25-42 | 280/315 | 2.2 | 15 | 858 | 2~18 |

| No. | Continent | Country |

| 1 | Europe | Germany, Britain, Russia, Ukraine, Netherlands, Belgium, Slovenia, Bosnia and Herzegovina, Poland, Lithuania, Moldova |

| 2 | America | United States, Mexico, Colombia, Chile, Bolivia, Ecuador, Trinidad and Tobago, Dominica, Bahamas, Puerto Rico, Honduras, El Salvador, Panama, Peru |

| 3 | Asia | Uzbekistan, Russia, Kazakhstan, China, Cambodia, Myanmar, Thailand, Malaysia, Canada, Indonesia, Philippines, Sri Lanka, Bangladesh, Nepal, Oman, Cyprus, Syria, Lebanon, Palestine, Pakistan, Israel, Iraq, Saudi Arabia Arabia, Yemen, UAE, Qatar, Afghanistan, Georgia, Bahrain |

| 4 | Africa | Algeria, Ethiopia, Kenya, Tanzania, Nigeria, Zimbabwe, Botswana, South Africa, Comoros, Malawi, Mozambique, Sudan, Tunisia, Libya, South Sudan, Somalia, Rwanda, Uganda, Mauritania, Senegal, Gambia, Guinea , Cape Verde, Sierra Leone, Ghana, Benin, Côte d’Ivoire, Burkina Faso, Madagascar, Cameroon, Equatorial Guinea, Congo (DRC), Zambia, Angola |

| 5 | Oceania | Australia, Papua New Guinea, New Zealand |

Zimbabwe Computer Control 3-5 T/H Chicken Feed Pellet Making Machine Production Line

Country: Zimbabwe

Capacity: 3-5 T/H

Qatar Farm Machinery 3-5 T/H Feed Pellet Making Machine Project

Country: Qatar

Capacity: 3-5 T/H

Botswana High Quality 1-2 T/H Animal Feed Pellet Making Machine Line Project

Country: Botswana

Capacity: 1-2 T/H

Solution

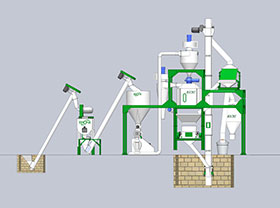

Easy to Operate 1-2 T/H Feed Pellet Production Line

Good Feedbacke 5-7 T/H Feed Pellet Production Line

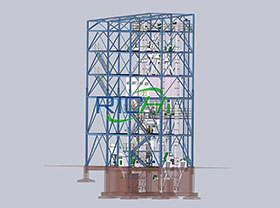

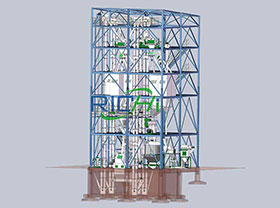

Good Quality 8-12 T/H Feed Pellet Production Line

High Performance 20-30 T/H Feed Pellet Production Line

Shrimp Feed Pellet Plant Production Line

Poultry Feed Pellet Plant Production Line

Ruminant Feed Pellet Plant Production Line

Livestock Feed Pellet Plant Production Line