Hotline:+86 18574103366

| |

Model:MZLH

Capacity:0.3 t/h-20 t/h

Applicable: Organic Fertilizer Pellet Mill Plant

Organic fertilizer pellet mill maker is the professional equipment for making organic fertilizer. It does not need any additive or binder to make pellets. As chicken, pig or other cattle have poor digestive ability, they can only digest 25% of nutrition ingredients; therefore, the other 75% of nutrition ingredients in feed are excreted with dung, as a result, the final manure organic fertilizer is contains rich nitrogen, phosphorus, potassium, organic matter, amino acid, protein, etc. Such fertilizer pellet machine can on one hand create economic benefit for investors, on the other hand make contribution to environmental protection.

Organic fertilizer is also called farm manure fertilizer, because this kind of fertilizer is made from cattle mature, such as chicken, duck, pig, cow, sheep, etc. As a kind of natural fertilizer, it is widely used in rural areas where grains, vegetables or other crops are planted. In the past, manure fertilizer was spread in the fields directly without machine processing, but its economic value was not fully developed.

In modern time, as organic fertilizer pellet mill is invented, manure fertilizer has been added value. For example, investors can make the manure into regular shape fertilizer pellets and packed into uniform bags for sale. Such processing can also improve the quality and effect of organic fertilizer.

| No. | Category | Raw materials list |

| 1 | Agricultural waste | straw, dregs of beans, cotton dregs, rice bran, biogas waste, mushroom waste, etc. |

| 2 | Animal waste | slaughterhouse waste, fish market waste, urine and dung of chicken, pig, cattle, sheep ducks, geese, goat, etc. |

| 3 | Industrial waste | wine lees waste, vinegar waste, manioc waste, sugar waste, etc. |

| 4 | Home waste | food waste, bones, the roots and leaves of vegetables, etc. |

| 5 | Mineral | humic acid, bentonite, dolomite, etc. |

| 6 | Sludge | river sludge, pond sludge, sewage sludge, city sludge, etc. |

1. Soil Structure

Because of the organic matter present in organic fertilizer, soil structure is improved and as a result the soil’s ability to hold onto water and nutrients increases.

2. Reduce Fertilizers and Pesticides

Although organic fertilizer can be more costly than synthetic, it can reduce the need for pesticides and the overall nitrogen, phosphorus and potassium requirements. Because of the reductions, organic fertilizer can be cost neutral and sometimes a cost savings.

3. Plant Damage Threat Avoided

Some synthetic fertilizers can cause plant damage to leaves and roots. This is less likely with organic fertilizers.

4. Microbes Thrive

Synthetic fertilizer consists of chemical molecules without carbon. These molecules can sometimes be disruptive and are not accessible to microbes. On the other hand, organic fertilizer is rich in organic matter, which helps microbes thrive. Organic fertilizer contains carbon as part of its chemical makeup; and it is the carbon, along with nitrogen, phosphorus and potassium that feeds microbes and enables them to make nutrients available for plants in a naturally occurring biological process.

5. Sustainable and Environmentally Friendly

Synthetic fertilizers runoff into our waterways harming marine life and water quality. Organic fertilizers do not run off as easily (if at all) and are associated with soil structure. According to the Organic Trade Association, organic fertilizer also increases species biodiversity by 30% compared with synthetic fertilizer.

One ton of sugarcane can produce about 300kg bagasse. The production of sugarcane bagasse per year in Brazil is 75~90 million tons. About 90% or more is used as fuel to supply power for factory. With wood pellets making machine, bagasse can be extruded into pellets fuel.

Some sugar mill owners sell their excess sugarcane bagasse pellets to other factories with boilers or export them to foreign countries. Recently many East Asian countries such as China have started imported large quantities of sugarcane bagasse pellets. An average size power plant usually consumes over 10,000 tonnes of sugarcane bagasse pellets every month.

With feed pellet mill, through high pressure and high temperature processing, bagasse can be used as animal feed instead of grass and other fodder materials. Bagasse feed pellets can mainly be used to feed cattle, cows, sheep, fish and so on.Years of experiments show that adding 38%~40% puffed bagasse in forage does good to animals’ healthy. The experimental data is as below:

In countries such as India, China, Colombia, Iran, Thailand and Argentina, bagasse is used in lieu of wood to create paper and pulp. Bagasse has good qualities for creating paper for mass production and distribution. It is also used to create thicker material boxes and boards as a substitute for plywood. Many companies even use it to build furniture.

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Capacity | 300-400kg/h | 500-700kg/h | 1.0-1.2 t/h | 2.0-2.5 t/h | 2.5-4 t/h | 3-4.5 t/h |

| Pellet Machine Power | 37kw | 55kw | 90kw | 110/132kw | 250/280kw | 280kw |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

Solution

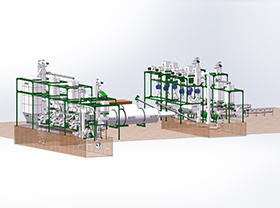

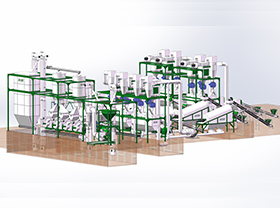

2-2.5 T/H Biomass Wood Pellet Production Line

4-5 T/H Biomass Wood Pellet Production Line

8-10 T/H Biomass Wood Pellet Production Line

24-30 T/H Biomass Wood Pellet Production Line

Wood Pellet Plant Production Line

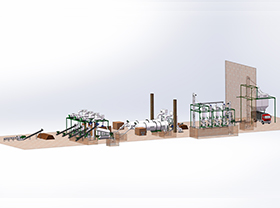

Biomass Pellet Plant Production Line

Alfalfa Pellet Plant Production Line

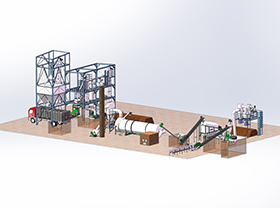

Organic Fertilizer Pellet Plant Production Line