Hotline:+86 18574103366

| |

Model:MZLH-768

Capacity:9-10 t/h

Applicable: organic fertilizer pellet plant

Organic fertilizer is also called farm manure fertilizer, because this kind of fertilizer is made from cattle mature, such as chicken, duck, pig, cow, sheep, etc. As a kind of natural fertilizer, it is widely used in rural areas where grains, vegetables or other crops are planted. In the past, manure fertilizer was spread in the fields directly without machine processing, but its economic value was not fully developed. In modern time, as organic fertilizer pellet mill is invented, manure fertilizer has been added value. For example, investors can make the manure into regular shape fertilizer pellets and packed into uniform bags for sale. Such processing can also improve the quality and effect of organic fertilizer. Richi Machinery big capacity good priCE MZLH768 9-10 t/h organic fertilizer pellet manufacturing machine compact structure, excellent workmanship, easy operation, long life, preferential factory direct sales prices, is a very cost-effective pelletizing equipment.

| No. | Category | Raw materials list |

| 1 | Agricultural waste | straw, dregs of beans, cotton dregs, rice bran, biogas waste, mushroom waste, etc. |

| 2 | Animal waste | slaughterhouse waste, fish market waste, urine and dung of chicken, pig, cattle, sheep ducks, geese, goat, etc. |

| 3 | Industrial waste | wine lees waste, vinegar waste, manioc waste, sugar waste, etc. |

| 4 | Home waste | food waste, bones, the roots and leaves of vegetables, etc. |

| 5 | Mineral | humic acid, bentonite, dolomite, etc. |

| 6 | Sludge | river sludge, pond sludge, sewage sludge, city sludge, etc. |

Vegetable growth

Arboriculture

Fruit growth

Viticulture

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Capacity | 1-2t/h | 3-4 t/h | 5-6 t/h | 7-8 t/h | 9-10 t/h | 10-12t/h |

| Pellet Machine Power | 37kw | 55kw | 90kw | 110/132kw | 250/280kw | 280kw |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

Solution

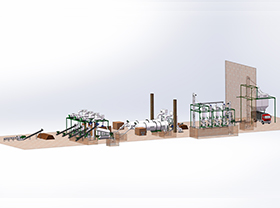

2-2.5 T/H Biomass Wood Pellet Production Line

4-5 T/H Biomass Wood Pellet Production Line

8-10 T/H Biomass Wood Pellet Production Line

24-30 T/H Biomass Wood Pellet Production Line

Wood Pellet Plant Production Line

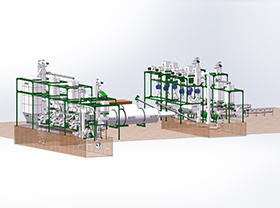

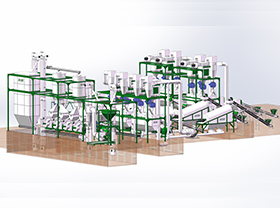

Biomass Pellet Plant Production Line

Alfalfa Pellet Plant Production Line

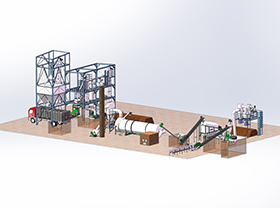

Organic Fertilizer Pellet Plant Production Line