Hotline:+86 18574103366

| |

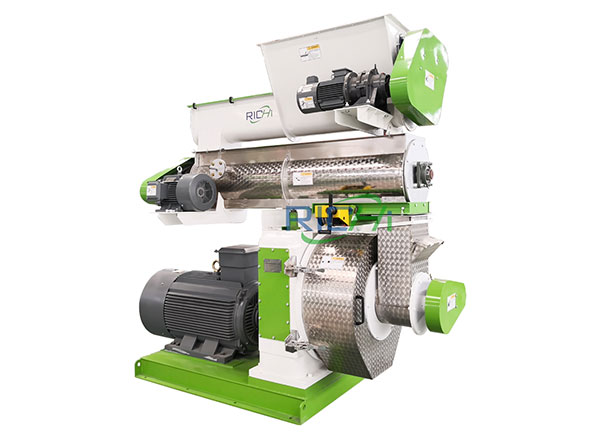

Model:MZLH-420

Capacity:1.5-2 t/h

Applicable: alfalfa grass pellet producing plant

Richi Machinery good stability most popular MZLH420 alfalfa grass pellet maker produces 1.5-2 t/h of alfalfa grass pellets per hour. The key of alfalfa grass pelletizing is the water content of the raw grass. First of all, we must measure the moisture content of the raw materials. Then, regulate it to an appropriate value by adding water or sun-dry. Researches show that the best moisture content for leguminous forage grass pellets is 14% to 16%. For Gramineae forage grass pellets it is 13% to 15%. In fact, grass pellets can also used as fuel for heating if the moisture are accurately controlled. Grass pellets may produce more ash than wood pellets, and the calorie in grass pellets is not so much wood pellets, but the grass pellets are still a well-accepted method in Europe for a long time. In a word, the grass pellets are an excellent choice for both feed and fuel.

| No. | Continent | Country |

| 1 | Europe | Germany, Britain, Russia, Ukraine, Netherlands, Belgium, Slovenia, Bosnia and Herzegovina, Poland, Lithuania, Moldova, Romania, Spain, Albania, Slovakia, Czech Republic, Austria |

| 2 | America | United States, Mexico, Colombia, Canada, Chile, Bolivia, Ecuador, Trinidad and Tobago, Dominica, Bahamas, Puerto Rico, Honduras, El Salvador, Panama, Peru, Brazil, Argentina, Jamaica |

| 3 | Asia | Uzbekistan, Russia, Kazakhstan, China, Vietnam, Cambodia, Myanmar, Thailand, Malaysia, Canada, Indonesia, Philippines, Sri Lanka, Bangladesh, Nepal, Oman, Cyprus, Syria, Lebanon, Palestine, Pakistan, Israel, Iraq , Saudi Arabia, Yemen, UAE, Qatar, Afghanistan, Georgia, Bahrain |

| 4 | Africa | Algeria, Ethiopia, Kenya, Tanzania, Nigeria, Zimbabwe, Botswana, South Africa, Comoros, Malawi, Mozambique, Sudan, Tunisia, Libya, South Sudan, Somalia, Rwanda, Uganda, Mauritania, Senegal, Gambia, Guinea , Cape Verde, Sierra Leone, Ghana, Benin, Côte d’Ivoire, Burkina Faso, Madagascar, Cameroon, Equatorial Guinea, Congo (DRC), Zambia, Angola |

| 5 | Oceania | Australia, Papua New Guinea, New Zealand |

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Capacity | 600-800kg/h | 800-1000kg/h | 1.5-2t/h | 3-4 t/h | 5-7 t/h | 8-10t/h |

| Pellet Machine Power | 37kw | 55kw | 90kw | 110/132kw | 250/280kw | 280kw |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

Solution

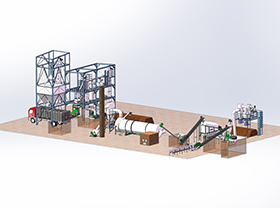

2-2.5 T/H Biomass Wood Pellet Production Line

4-5 T/H Biomass Wood Pellet Production Line

8-10 T/H Biomass Wood Pellet Production Line

24-30 T/H Biomass Wood Pellet Production Line

Wood Pellet Plant Production Line

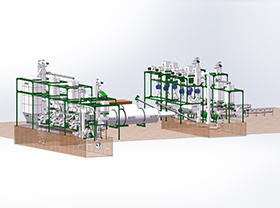

Biomass Pellet Plant Production Line

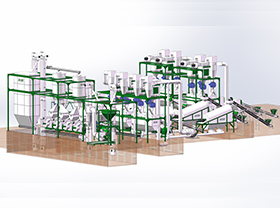

Alfalfa Pellet Plant Production Line

Organic Fertilizer Pellet Plant Production Line