Hotline:+86 18574103366

| |

Model:MZLH

Capacity:0.3 t/h-20 t/h

Applicable: Hemp Pellet Plant

The fuel pellet market is currently dominated by premium grade wood pellets, with some niche companies also offering grass and straw pellets. However, the waste wood used for fuel pellets is a limited supply and grass and straw pellets produce more ash, plus clinker and corrosion issues, so many stoves and boilers cannot use them.

The demand for woody shiv is still in its infancy in Canada and the UK and the United States is interested in hemp harvesting and renewable energy. With the Farmer’s Almanac reporting a colder than usual winter season this year, legislators need to step up efforts in recognizing hemp as a natural alternative for energy.

Hemp pellets produce around 2% ash and can be used in a large range of pellet burners currently on the market today. Hemp is less corrosive to burn than wood pellets, creates less ash, and always has the same high quality as what you find in premium grade wood pellets. This product comes from the shiv of the hemp stalk and has no possibility of including any additional material that can lead to a lower grade of quality.

Before we discuss the benefits of hemp pellets, we need to address the issues other biomass fuel pellets experience during combustion. The pellet fuel market is now developing to include other biomass energy crops such as miscanthus, switchgrass and hemp. All of these biomass materials can be collected and processed in the pellet mill to produce grass pellets which are suitable for fuel-flexible pellet stoves and boilers. However different biomass materials produce different combustion results. We have seen this through our experiments with our own biomass pellet boiler.

While miscanthus and switchgrass both have their merits, they also have their issues. The problem with most grasses and straws is during combustion they produce a significantly higher ash content than say premium wood pellets. Many pellet stoves and boilers are designed specifically to burn wood pellets with an ash content below 2%. Therefore using grass pellets can often create issues. With some biomass pellets, the ash content can be as high as 10%. Therefore this either means the ash bin fills up really quickly or in some cases, the pellet stove or boiler can stop working altogether.

The other problem with some biomass fuel pellets made from grasses and straws is clinker formations. Clinkers are where the ash melts and forms together into a clump. Most pellet stoves and boilers have no means to deal with clinkers, as they were specifically designed to run on wood pellets. When the clinker is hot it’s soft and sticky. However, when it cools it’s as hard as glass. Luckily our pellet boiler is very durable and able to deal with such clinkers. However, most pellet stoves are not. And a clinker such as that shown in the image above could do a small pellet stove some serious damage.

The hemp plant Cannabis sativa Linn, referring to industrial hemp, is a high-yielding annual industrial crop grown providing fibers from hemp stalk and oil from hemp seeds. More than 30 countries grow hemp, with China being the largest hemp producing and exporting country. Europe and Canada are also important actors in the global hemp market. Traditionally, hemp as a fiber plant has been used for the production of apparels, fabrics, papers, cordages and building materials. The hurds, as waste by-product of fiber production, were used for bedding of animals, the seeds for human nutrition, e.g., as flour, and the oil for a wide range of purposes, from cooking to cosmetics. Hemp has also been an important crop throughout human history for medicine. Other more recent applications include materials for insulation and furniture, automotive composites for interior applications and motor vehicle parts, bioplastics, jewelry and fashion sectors, animal feed, animal bedding, and energy and fuel production.

Currently, the construction and insulation sector, paper and textile industries, and food and nutrition domains are the main markets while the cosmetics and automotive sector are growing markets. Innovative applications, e.g., in the medical and therapeutic domains, cosmeceuticals, phytoremediation, acoustic domain, wastewater treatment, biofuels, biopesticides and biotechnology, open new challenges.

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Capacity | 600-800kg/h | 800-1000kg/h | 1.5-2t/h | 3-4 t/h | 5-7 t/h | 8-10t/h |

| Pellet Machine Power | 37kw | 55kw | 90kw | 110/132kw | 250/280kw | 280kw |

| Final Pellet | 1-12mm | 1-12mm | 1-12mm | 1-12mm | 1-12mm | 1-12mm |

| No. | Continent | Country |

| 1 | Europe | Germany, Britain, Russia, Ukraine, Netherlands, Belgium, Slovenia, Bosnia and Herzegovina, Poland, Lithuania, Moldova, Romania, Spain, Albania, Slovakia, Czech Republic, Austria |

| 2 | America | United States, Mexico, Colombia, Canada, Chile, Bolivia, Ecuador, Trinidad and Tobago, Dominica, Bahamas, Puerto Rico, Honduras, El Salvador, Panama, Peru, Brazil, Argentina, Jamaica |

| 3 | Asia | Uzbekistan, Russia, Kazakhstan, China, Vietnam, Cambodia, Myanmar, Thailand, Malaysia, Canada, Indonesia, Philippines, Sri Lanka, Bangladesh, Nepal, Oman, Cyprus, Syria, Lebanon, Palestine, Pakistan, Israel, Iraq , Saudi Arabia, Yemen, UAE, Qatar, Afghanistan, Georgia, Bahrain |

| 4 | Africa | Algeria, Ethiopia, Kenya, Tanzania, Nigeria, Zimbabwe, Botswana, South Africa, Comoros, Malawi, Mozambique, Sudan, Tunisia, Libya, South Sudan, Somalia, Rwanda, Uganda, Mauritania, Senegal, Gambia, Guinea , Cape Verde, Sierra Leone, Ghana, Benin, Côte d’Ivoire, Burkina Faso, Madagascar, Cameroon, Equatorial Guinea, Congo (DRC), Zambia, Angola |

| 5 | Oceania | Australia, Papua New Guinea, New Zealand |

Solution

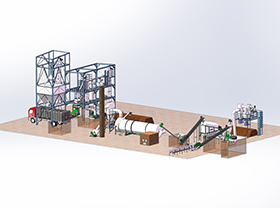

2-2.5 T/H Biomass Wood Pellet Production Line

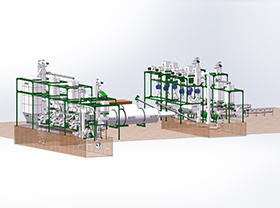

4-5 T/H Biomass Wood Pellet Production Line

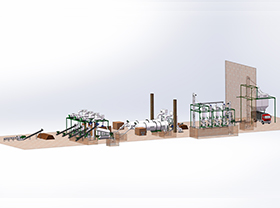

8-10 T/H Biomass Wood Pellet Production Line

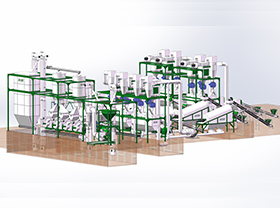

24-30 T/H Biomass Wood Pellet Production Line

Wood Pellet Plant Production Line

Biomass Pellet Plant Production Line

Alfalfa Pellet Plant Production Line

Organic Fertilizer Pellet Plant Production Line